Why Find a New Path, Transforming from System Integrator to Key Equipment Supplier?---Interviewing Tang Shuzhe, Director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd.

Company News | 2020-05-26 14:29 Page views:

Recently, Tang Shuzhe, director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd., has been interviewed by a world-class professional logistics media, MATERIAL FLOW periodical office. He deeply analyzed the topic “ROBO opened a new path by changing from SI to key equipment supplier”.

The content edited by Editorial Department of MATERIAL FLOW periodical office is as follows:

Mr. Tang Shuzhe, Director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd.

30 years ago, the enterprise of European descent had a long-term vision and was down-to-earth with the craftsman's heart, pursuing steady and long-term growth; 20 years ago, the founder had insights into opportunities, successfully predicted the industry trend, and opened a new path in logistics automation; He came to China 5 years ago and achieved amazing blowout development.

“He did not except such success,” Tang Shuzhe, the director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd.(hereinafter referred to as ROBO) said when talking about Mr. Volgger, the founder of ROBO, and the achievement of China Region “It is believed the success of Chinese market is reasonable, but the achievement is unexpected.”

In the first 5-year of developing business in China, ROBO(China) handed in an amazing answer. With rich experience on projects and technologies, the company's annual compound growth rate exceeded 40% by 2019 with the sales of 2500 sets. Mr. Tang said, it only took ROBO 5 years to complete the 30-year road of its headquarter in Austria depending on the vast and dynamic intelligent logistics market in China.

01 Unusual Corporation Transformation Path

Incorporate Things of Diverse Nature and Rise Abruptly based on Accumulated Strength

“At the moment, ROBO was a real system integrator” At the beginning of its establishment in 1988, ROBO mainly provided optical fiber and cable industry with internal-manufacturing logistics system solutions. Despite the great number of strong rivals in European market, ROBO made a breakthrough and became the biggest automation manufacturer in optical fiber and cable industry worldwide. “We are a typical small but beautiful enterprise in Europe, but we always focus on the intelligent logistics industry and concentrate on exploring automated logistics technology," Mr. Tang talked with assurance.

ROBO’s influence is definitely more than this. For instance, the automated logistics system project of Swarovski, which has attracted the attention of the industry, is also its pride. ROBO not only accumulated great capacity of highly automated solutions for manufacturing enterprises, but also developed corresponding core equipment through construction of projects in various industries.

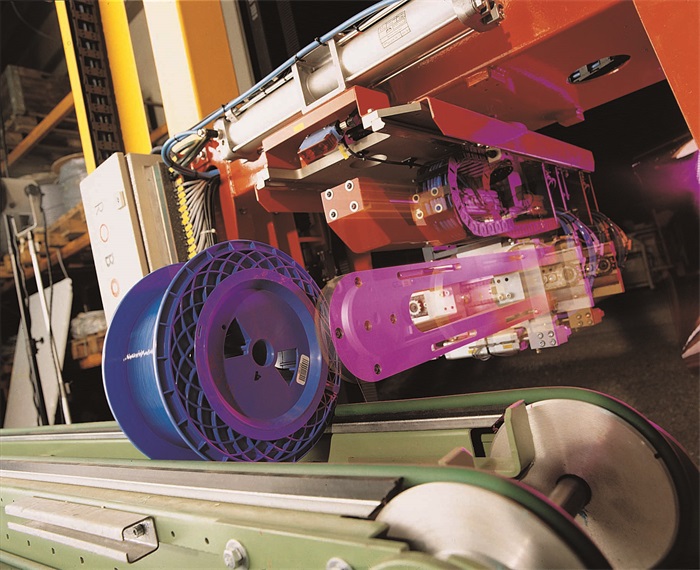

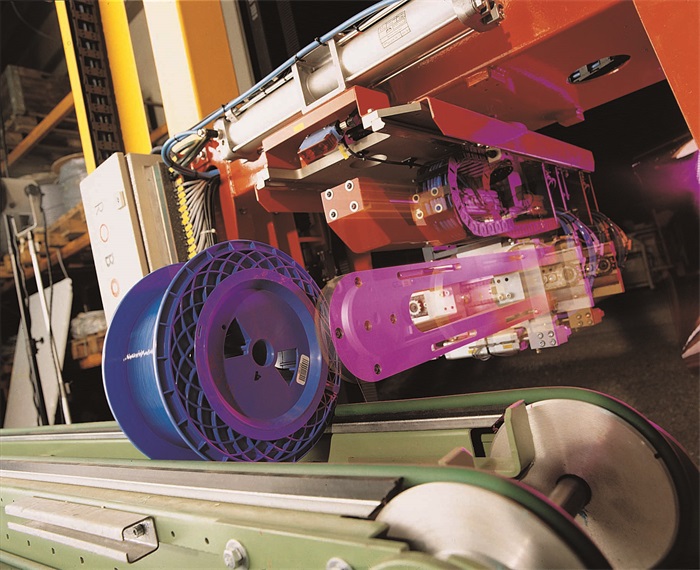

Cheetah Model

Insight into the Opportunities and Successful Transformation

After 2000, changes in supply and demand in the entire market prompted ROBO to transform urgently. Through the cooperation with large integrators, the founder of ROBO, Mr. Volgger, found that the company possesses a high professional capacity of manufacturing logistics automation equipment. Thus, the idea of defining manufacturing equipment as the company’s core competitiveness came into his mind, he decided to change it from a system integrator to an equipment supplier that mainly provides stacker crane. And such related products as multi-shuttle and conveyor were derived.

Unlike the transformation of ordinary equipment manufacturer who transformed into system integrator, ROBO found a development path that suits to itself. Mr. Tang said: “opening a new path, making a reverse transformation, from system integrator to equipment manufacturer, is quite successful! ROBO is like an automobile engine manufacturer, formed a close relationship of supply chain cooperation with system integrators who play the role of vehicle operator, and help them with the development, design and manufacturing and provide key equipment.” For system integrators, he explained, the joining of ROBO is a supplement and improvement for their key equipment. The joint development, technology sharing and customization of requirements will help the integrators to further enhance their capability to capture projects.

02 Localization Strategy Win Speedy Success

In China, local integrators suffer from weak domestic core professional technical capabilities. Although they have new ideas and a team of young technical planning engineers, they still lack the capability to manufacture key equipment. After entering China, the company cooperated with Chinese local integrators and took advantage of the trend to provide them with mature technology of core equipment to fill the gap in this regard.

Predict the Market Trends Successfully

Earlier, ROBO believed that with the gradual disappearance of China ’s demographic dividend, the cost of land is rising, and the scale of a large number of Chinese head manufacturing enterprises and distribution enterprises is gradually expanding, prompting it to urgently improve its own manufacturing level. Therefore, it is inevitable to introduce automation and intelligent technology. In those days, the application of logistics automation in China mainly centered on such non-market industries as tobacco, electric power and pharmaceuticals. In order to seize the market, the head enterprises of market industries also chose to introduce automation and intelligent technology and equipment.

Nonetheless, most customers were reluctant to undertake the over-invested originally imported equipment, nor did they trust China's equipment production technology, product quality and reliability at the time. On this occasion, ROBO successfully introduced the Austrian technology into China and completed the localized manufacturing. In this way, the investment has been greatly reduced and the product quality has been ensured, the cost performance has been improved with the customer needs met.

Implementation of Full Localization

Full localization is ROBO’s operating strategy in China. ROBO established a team of experts in China to better understand the demand, culture and characteristics of the Chinese market and being more accessible. According to Mr. Tang, the core members of the team are all top technical experts in the field of stacker cranes, and the relevant leadership has been plowing in the automated storage industry for 30 years.

It is precisely because these expert teams inherited the mature automated logistics equipment technology from ROBO_Austria, ROBO can transform advanced European technology into a process that manufacturing in local China. Tang Shuzhe said that due to the differences in process standards and supply chain systems between China and Occident, it is not possible to successfully copy only with drawings. Only experienced technical and manufacturing experts can understand differences between their standard process patterns and those between supply chains. And then complete the transformation of drawings and supply chain.

03 Each Series Product has Its Advantages

The first series of product ROBO launched after its establishment in China, which is also the star product commonly used in the stereoscopic warehouse in the market--Panther Series Standard Unit Load Stacker Crane. As of now, this model has upgraded to the third-generation new type of product. Mr. Tang introduced that the technology of the third generation Panther keeps the original high reliability, in the meantime, it also offers high throughput capacity to the largest extent on the basis of long-term continuous operation. Comparing with the same model, for the third generation Panther of ROBO, the travel speed of it can be as fast as 240m/s, and its acceleration speed can be as fast as 1m/s2. Mr. Tang said, these professional technologies are 30% higher than the stacker cranes of other existing domestic brands.

Unlike the Panther Series, which has both speed and reliability, the Cheetah Series of ROBO pursues high throughput and high accelerated speed, it suits for small-size goods warehouses with high demand or cache warehouses with high throughput; while the Bull Series focuses more on load capacity, ROBO has designed and manufactured a special stacker crane with the load capacity of 12 ton. In all series products of the company, localization rate of other models all exceed 90%, excluding the Cheetah, and each series can suit to various storage environment, including low temperature storage.

Tang believed the hoisting capacity is one of the important indexes to check the technology of stacker cranes because the stacker crane technology is originated from crane. Among all the indexes, the strength of frame structure, the structure and mode of hoisting technology, and such details as traction, winding, rollover and tipping determine the load of stacker cranes comprehensively. He said, the load of stacker crane manufactured by domestic system integrator cannot be over 2 ton, while ROBO’s stacker crane with load capacity of 2-2.5 ton or even more is a kind of special equipment, and it’s also one of ROBO’s strengths.

Cheetah TMBS-SD-200-5.800

04 Profound Accumulation and Intensive Rise

Many people believe ROBO’s development in China is like “a high building rise from the flat ground”, but it is not known that its development is gained step by step. Mr. Tang said that the company’s rise is supported by the professional accumulation of its headquarter in Austria and the technical accumulation of its team of senior Chinese experts, and also because it met the trend of blowout of logistics automation market in China. He analyzed that the manufacturing of stacker cranes is mainly done by system integrator in the first place, and the dealers and mechanical manufacturers do not possess the real manufacturing capacity that integrates stacker crane’s design, R&D and manufacturing, nor the design and development capability of electrical part, software and control system. Therefore, ROBO can be brought to the public eye, it is more like “it is the times produce their heroes”.

Equal Emphasis on Product and Service

From global business to focusing on Asian-Pacific region, and from China to the world, ROBO(China)’s products have been exported to such Southeast Asian countries as Thailand, Indonesia and Vietnam, and even some developed countries like Singapore, New Zealand, Sweden and Japan. Taking the order from Japan customer is one of ROBO’s prides in international market. It is known to all that serious production and fixed trading mode are prevalent in Japan’s industrial organization structure, and the import market closure caused by industrial protection structure of Japanese government. Besides, Japan itself has a powerful strength in stereoscopic warehouse automation logistics technology. as a consequence, it is a sea of troubles for a non-local enterprise to enter Japan’s market.

Taking a Japanese machinery manufacturing enterprise as an example, Tang Shuzhe believes that customers chose ROBO not only because of the high quality of its products, but also because they value ROBO’s perfect service system. Mr. Tang recalled that when the customer hesitated and had no idea to choose which company except domestic suppliers, and he couldn’t accept import European equipment directly; the customer found a company from European and American area that manufactures stacker crane in China, the perfect service and product satisfied him a lot, the customer chose ROBO finally.

Large-scale Operation and Concentration on Manufacturing

As the growing of the market scale, the advantage of ROBO’s stacker crane business scale emerges, Mr. Tang analyzed, because of the small scale of the original logistics automation industry, the division of labor in the industrial chain cannot take shape, which hinders the enlarging of logistics automation equipment manufacturing scale.

on the other hand, some corresponding enterprises cannot undertake the large investment of automated product line due to lack of resources, “some enterprises cannot put into plenty of resources and focus on equipment-manufacturing like professional manufacturers do”, Mr. Tang said, “while ROBO can do this”.

In the future, ROBO will continue to adhere to the concept of craftsmen and do more work on its products seriously, and the company will keep on establishing its own competitive characteristics and form a win-win supply chain system with integrators.

Why Find a New Path, Transforming from System Integrator to Key Equipment Supplier?---Interviewing Tang Shuzhe, Director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2020-05-26 14:29

- Views:

(Summary description)

Why Find a New Path, Transforming from System Integrator to Key Equipment Supplier?---Interviewing Tang Shuzhe, Director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd.

(Summary description)

- Categories:Company News

- Author:

- Origin:

- Time of issue:2020-05-26 14:29

- Views:

Recently, Tang Shuzhe, director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd., has been interviewed by a world-class professional logistics media, MATERIAL FLOW periodical office. He deeply analyzed the topic “ROBO opened a new path by changing from SI to key equipment supplier”.

The content edited by Editorial Department of MATERIAL FLOW periodical office is as follows:

Mr. Tang Shuzhe, Director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd.

30 years ago, the enterprise of European descent had a long-term vision and was down-to-earth with the craftsman's heart, pursuing steady and long-term growth; 20 years ago, the founder had insights into opportunities, successfully predicted the industry trend, and opened a new path in logistics automation; He came to China 5 years ago and achieved amazing blowout development.

“He did not except such success,” Tang Shuzhe, the director and General Manager of ROBO Technologies Automation (Suzhou) Co., Ltd.(hereinafter referred to as ROBO) said when talking about Mr. Volgger, the founder of ROBO, and the achievement of China Region “It is believed the success of Chinese market is reasonable, but the achievement is unexpected.”

In the first 5-year of developing business in China, ROBO(China) handed in an amazing answer. With rich experience on projects and technologies, the company's annual compound growth rate exceeded 40% by 2019 with the sales of 2500 sets. Mr. Tang said, it only took ROBO 5 years to complete the 30-year road of its headquarter in Austria depending on the vast and dynamic intelligent logistics market in China.

01 Unusual Corporation Transformation Path

Incorporate Things of Diverse Nature and Rise Abruptly based on Accumulated Strength

“At the moment, ROBO was a real system integrator” At the beginning of its establishment in 1988, ROBO mainly provided optical fiber and cable industry with internal-manufacturing logistics system solutions. Despite the great number of strong rivals in European market, ROBO made a breakthrough and became the biggest automation manufacturer in optical fiber and cable industry worldwide. “We are a typical small but beautiful enterprise in Europe, but we always focus on the intelligent logistics industry and concentrate on exploring automated logistics technology," Mr. Tang talked with assurance.

ROBO’s influence is definitely more than this. For instance, the automated logistics system project of Swarovski, which has attracted the attention of the industry, is also its pride. ROBO not only accumulated great capacity of highly automated solutions for manufacturing enterprises, but also developed corresponding core equipment through construction of projects in various industries.

Cheetah Model

Insight into the Opportunities and Successful Transformation

After 2000, changes in supply and demand in the entire market prompted ROBO to transform urgently. Through the cooperation with large integrators, the founder of ROBO, Mr. Volgger, found that the company possesses a high professional capacity of manufacturing logistics automation equipment. Thus, the idea of defining manufacturing equipment as the company’s core competitiveness came into his mind, he decided to change it from a system integrator to an equipment supplier that mainly provides stacker crane. And such related products as multi-shuttle and conveyor were derived.

Unlike the transformation of ordinary equipment manufacturer who transformed into system integrator, ROBO found a development path that suits to itself. Mr. Tang said: “opening a new path, making a reverse transformation, from system integrator to equipment manufacturer, is quite successful! ROBO is like an automobile engine manufacturer, formed a close relationship of supply chain cooperation with system integrators who play the role of vehicle operator, and help them with the development, design and manufacturing and provide key equipment.” For system integrators, he explained, the joining of ROBO is a supplement and improvement for their key equipment. The joint development, technology sharing and customization of requirements will help the integrators to further enhance their capability to capture projects.

02 Localization Strategy Win Speedy Success

In China, local integrators suffer from weak domestic core professional technical capabilities. Although they have new ideas and a team of young technical planning engineers, they still lack the capability to manufacture key equipment. After entering China, the company cooperated with Chinese local integrators and took advantage of the trend to provide them with mature technology of core equipment to fill the gap in this regard.

Predict the Market Trends Successfully

Earlier, ROBO believed that with the gradual disappearance of China ’s demographic dividend, the cost of land is rising, and the scale of a large number of Chinese head manufacturing enterprises and distribution enterprises is gradually expanding, prompting it to urgently improve its own manufacturing level. Therefore, it is inevitable to introduce automation and intelligent technology. In those days, the application of logistics automation in China mainly centered on such non-market industries as tobacco, electric power and pharmaceuticals. In order to seize the market, the head enterprises of market industries also chose to introduce automation and intelligent technology and equipment.

Nonetheless, most customers were reluctant to undertake the over-invested originally imported equipment, nor did they trust China's equipment production technology, product quality and reliability at the time. On this occasion, ROBO successfully introduced the Austrian technology into China and completed the localized manufacturing. In this way, the investment has been greatly reduced and the product quality has been ensured, the cost performance has been improved with the customer needs met.

Implementation of Full Localization

Full localization is ROBO’s operating strategy in China. ROBO established a team of experts in China to better understand the demand, culture and characteristics of the Chinese market and being more accessible. According to Mr. Tang, the core members of the team are all top technical experts in the field of stacker cranes, and the relevant leadership has been plowing in the automated storage industry for 30 years.

It is precisely because these expert teams inherited the mature automated logistics equipment technology from ROBO_Austria, ROBO can transform advanced European technology into a process that manufacturing in local China. Tang Shuzhe said that due to the differences in process standards and supply chain systems between China and Occident, it is not possible to successfully copy only with drawings. Only experienced technical and manufacturing experts can understand differences between their standard process patterns and those between supply chains. And then complete the transformation of drawings and supply chain.

03 Each Series Product has Its Advantages

The first series of product ROBO launched after its establishment in China, which is also the star product commonly used in the stereoscopic warehouse in the market--Panther Series Standard Unit Load Stacker Crane. As of now, this model has upgraded to the third-generation new type of product. Mr. Tang introduced that the technology of the third generation Panther keeps the original high reliability, in the meantime, it also offers high throughput capacity to the largest extent on the basis of long-term continuous operation. Comparing with the same model, for the third generation Panther of ROBO, the travel speed of it can be as fast as 240m/s, and its acceleration speed can be as fast as 1m/s2. Mr. Tang said, these professional technologies are 30% higher than the stacker cranes of other existing domestic brands.

Unlike the Panther Series, which has both speed and reliability, the Cheetah Series of ROBO pursues high throughput and high accelerated speed, it suits for small-size goods warehouses with high demand or cache warehouses with high throughput; while the Bull Series focuses more on load capacity, ROBO has designed and manufactured a special stacker crane with the load capacity of 12 ton. In all series products of the company, localization rate of other models all exceed 90%, excluding the Cheetah, and each series can suit to various storage environment, including low temperature storage.

Tang believed the hoisting capacity is one of the important indexes to check the technology of stacker cranes because the stacker crane technology is originated from crane. Among all the indexes, the strength of frame structure, the structure and mode of hoisting technology, and such details as traction, winding, rollover and tipping determine the load of stacker cranes comprehensively. He said, the load of stacker crane manufactured by domestic system integrator cannot be over 2 ton, while ROBO’s stacker crane with load capacity of 2-2.5 ton or even more is a kind of special equipment, and it’s also one of ROBO’s strengths.

Cheetah TMBS-SD-200-5.800

04 Profound Accumulation and Intensive Rise

Many people believe ROBO’s development in China is like “a high building rise from the flat ground”, but it is not known that its development is gained step by step. Mr. Tang said that the company’s rise is supported by the professional accumulation of its headquarter in Austria and the technical accumulation of its team of senior Chinese experts, and also because it met the trend of blowout of logistics automation market in China. He analyzed that the manufacturing of stacker cranes is mainly done by system integrator in the first place, and the dealers and mechanical manufacturers do not possess the real manufacturing capacity that integrates stacker crane’s design, R&D and manufacturing, nor the design and development capability of electrical part, software and control system. Therefore, ROBO can be brought to the public eye, it is more like “it is the times produce their heroes”.

Equal Emphasis on Product and Service

From global business to focusing on Asian-Pacific region, and from China to the world, ROBO(China)’s products have been exported to such Southeast Asian countries as Thailand, Indonesia and Vietnam, and even some developed countries like Singapore, New Zealand, Sweden and Japan. Taking the order from Japan customer is one of ROBO’s prides in international market. It is known to all that serious production and fixed trading mode are prevalent in Japan’s industrial organization structure, and the import market closure caused by industrial protection structure of Japanese government. Besides, Japan itself has a powerful strength in stereoscopic warehouse automation logistics technology. as a consequence, it is a sea of troubles for a non-local enterprise to enter Japan’s market.

Taking a Japanese machinery manufacturing enterprise as an example, Tang Shuzhe believes that customers chose ROBO not only because of the high quality of its products, but also because they value ROBO’s perfect service system. Mr. Tang recalled that when the customer hesitated and had no idea to choose which company except domestic suppliers, and he couldn’t accept import European equipment directly; the customer found a company from European and American area that manufactures stacker crane in China, the perfect service and product satisfied him a lot, the customer chose ROBO finally.

Large-scale Operation and Concentration on Manufacturing

As the growing of the market scale, the advantage of ROBO’s stacker crane business scale emerges, Mr. Tang analyzed, because of the small scale of the original logistics automation industry, the division of labor in the industrial chain cannot take shape, which hinders the enlarging of logistics automation equipment manufacturing scale.

on the other hand, some corresponding enterprises cannot undertake the large investment of automated product line due to lack of resources, “some enterprises cannot put into plenty of resources and focus on equipment-manufacturing like professional manufacturers do”, Mr. Tang said, “while ROBO can do this”.

In the future, ROBO will continue to adhere to the concept of craftsmen and do more work on its products seriously, and the company will keep on establishing its own competitive characteristics and form a win-win supply chain system with integrators.