Academic Innovation Recognized Again | ROBO Proposes Design of Heavy-Load Coil Stacker

Company News | 2022-03-29 17:06 Page views:

Recently, the academic paper "Design of Heavy-load Coil Stacker" written by the mechanical design and R&D experts of the ROBO Engineering Center was successfully included in the industry authoritative academic journal "Logistics Technology and Application", directly attacking the pain points of industrial application with advanced academic achievements , once again confirming that ROBO's innovative ability in the non-standard design of core equipment stackers has been recognized by academic authorities, leading intelligent logistics with strength.

Innovation begins with demand

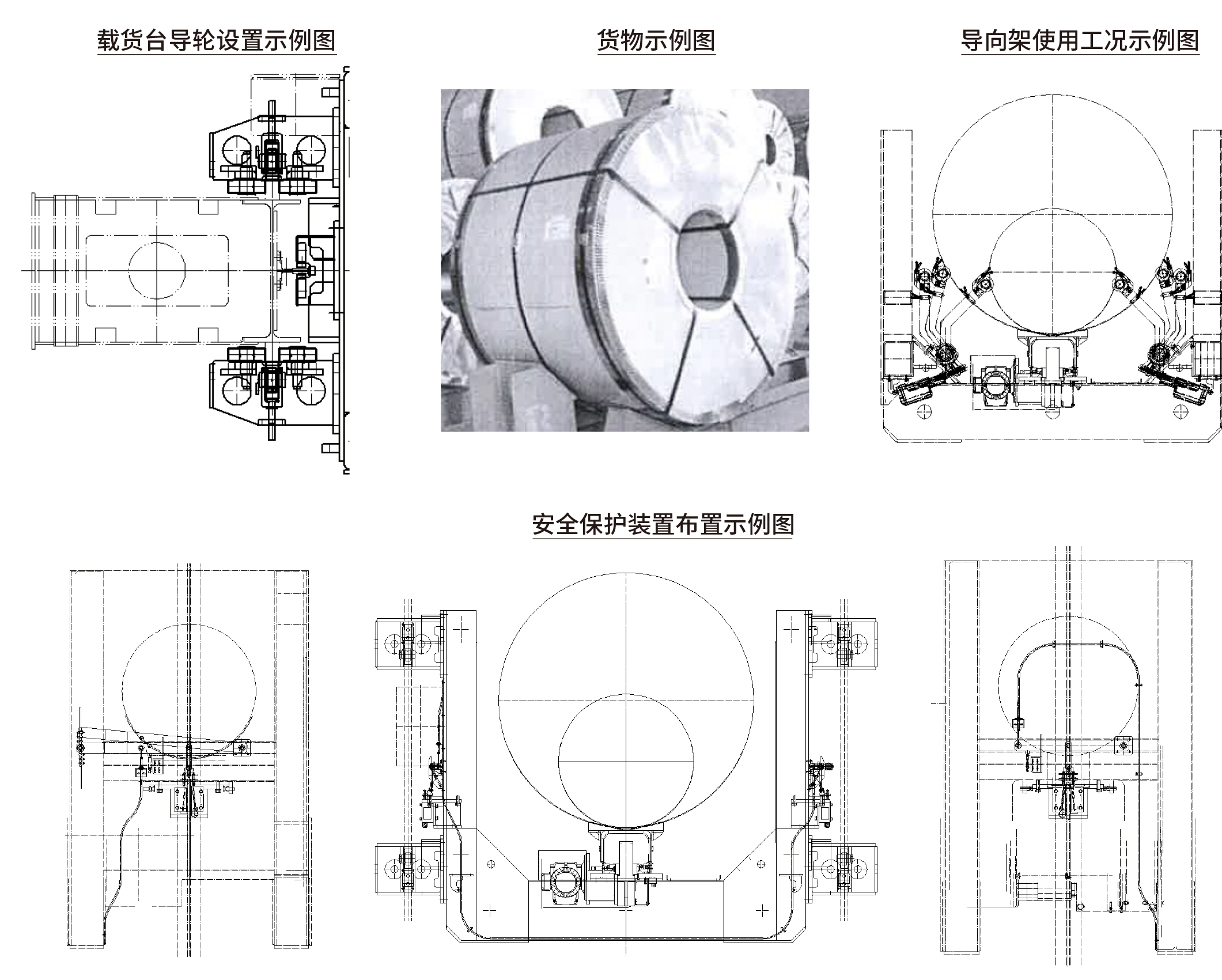

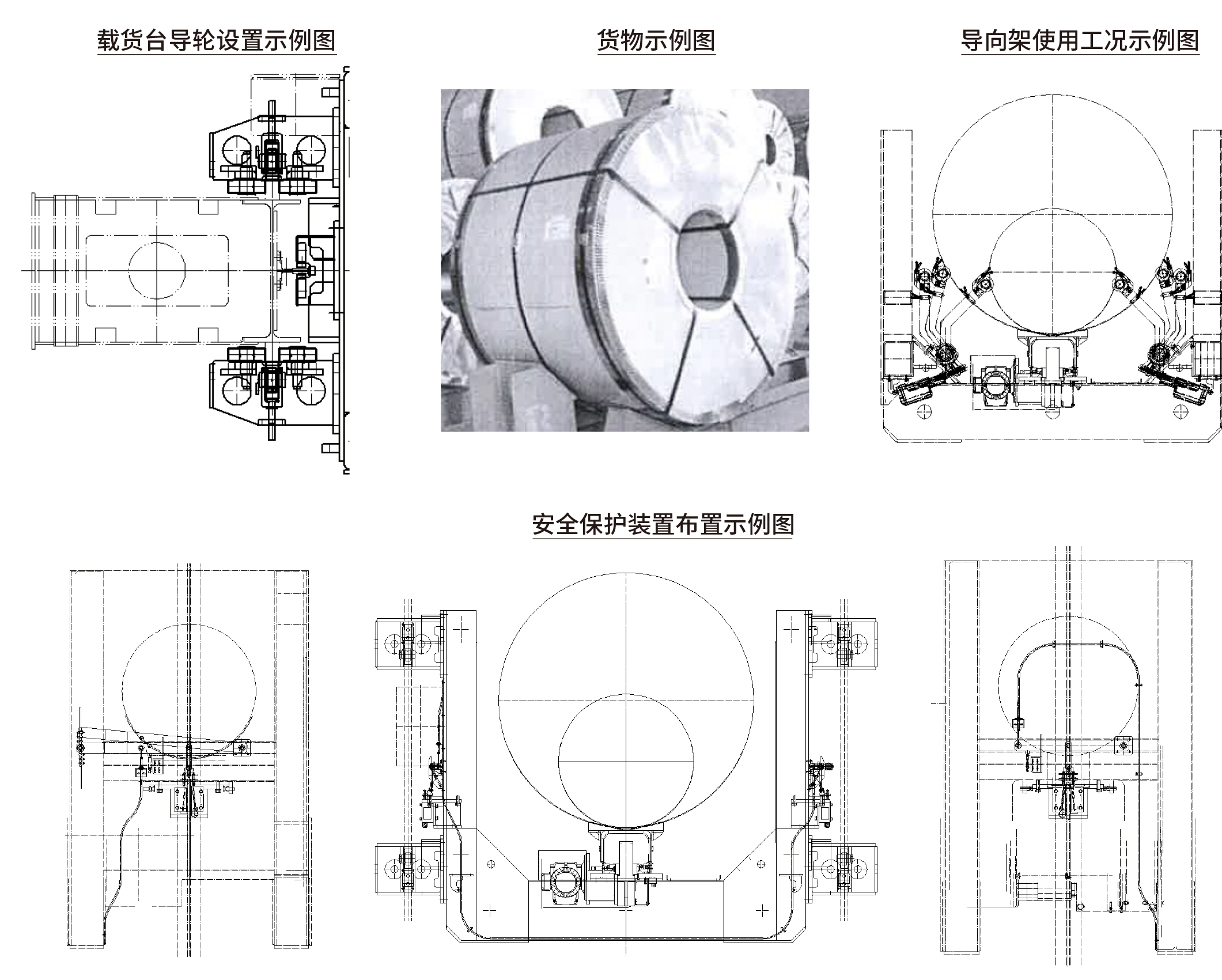

Grasping the real needs and development trends of customer scenarios is the core driving force of ROBO technology research and development. This paper fully demonstrates this differentiated competitive advantage, and proposes an innovative research and development demonstration of a stacker for transporting heavy-load coiled goods in a non-standard logistics scenario. Aiming at the characteristics that coiled goods cannot be accessed by conventional pallets in traditional logistics scenarios, and metal coils and paper rolls are prone to deformation and damage when they are pressed, a special guide frame mechanism is designed to fix the coiled goods. The type fork can prevent the roll material from moving and rolling, so that the goods can be stored more stably and perfectly fill the market gap.

Upgrading of academic enabling products

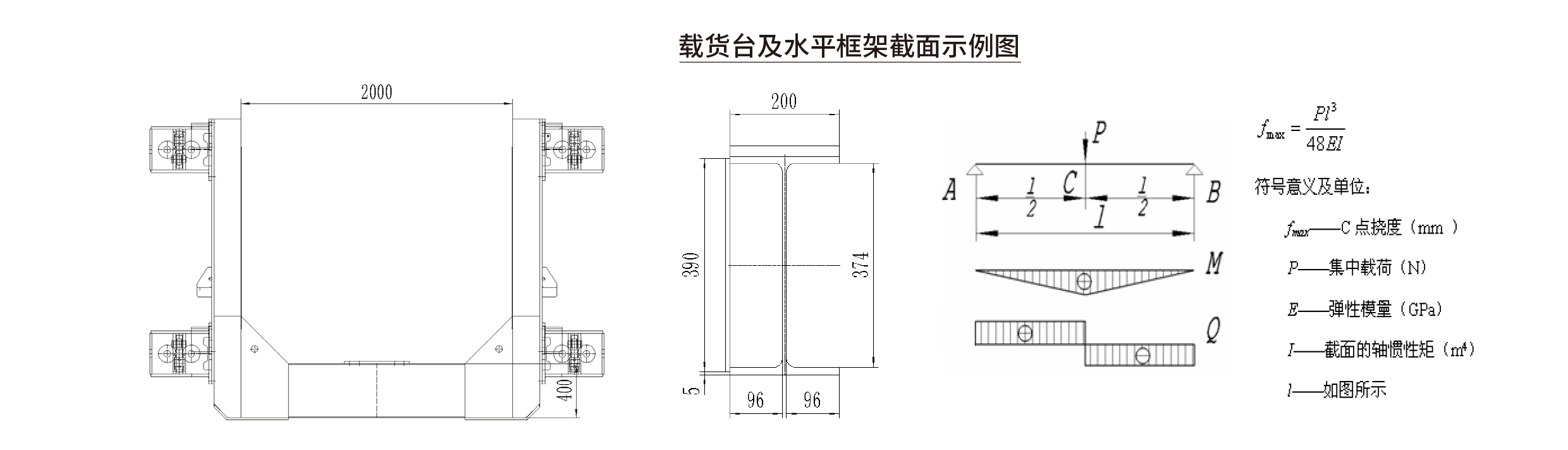

Due to the heavy and large size of the goods carried in the heavy-load logistics scenario, in order to improve the safety and stability of the stacker during high-speed operation, we put forward the following design arguments in terms of mechanical structure.

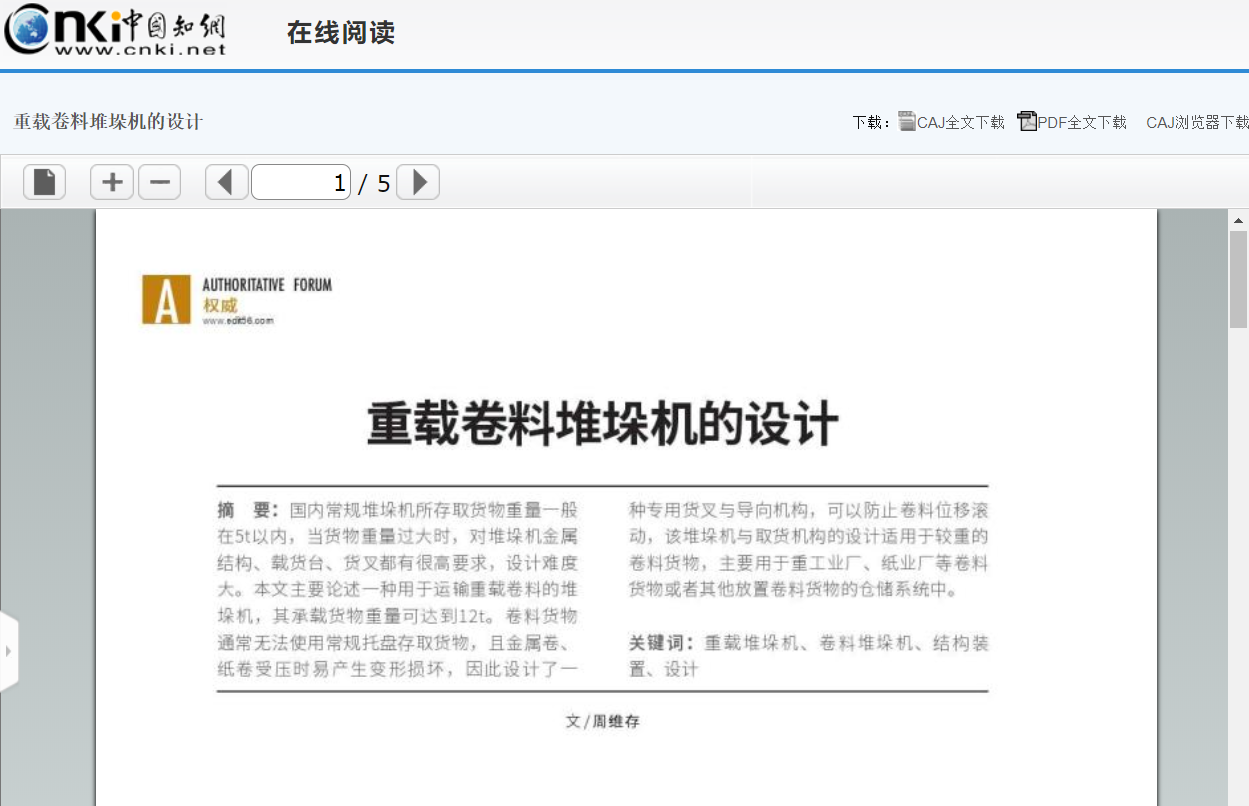

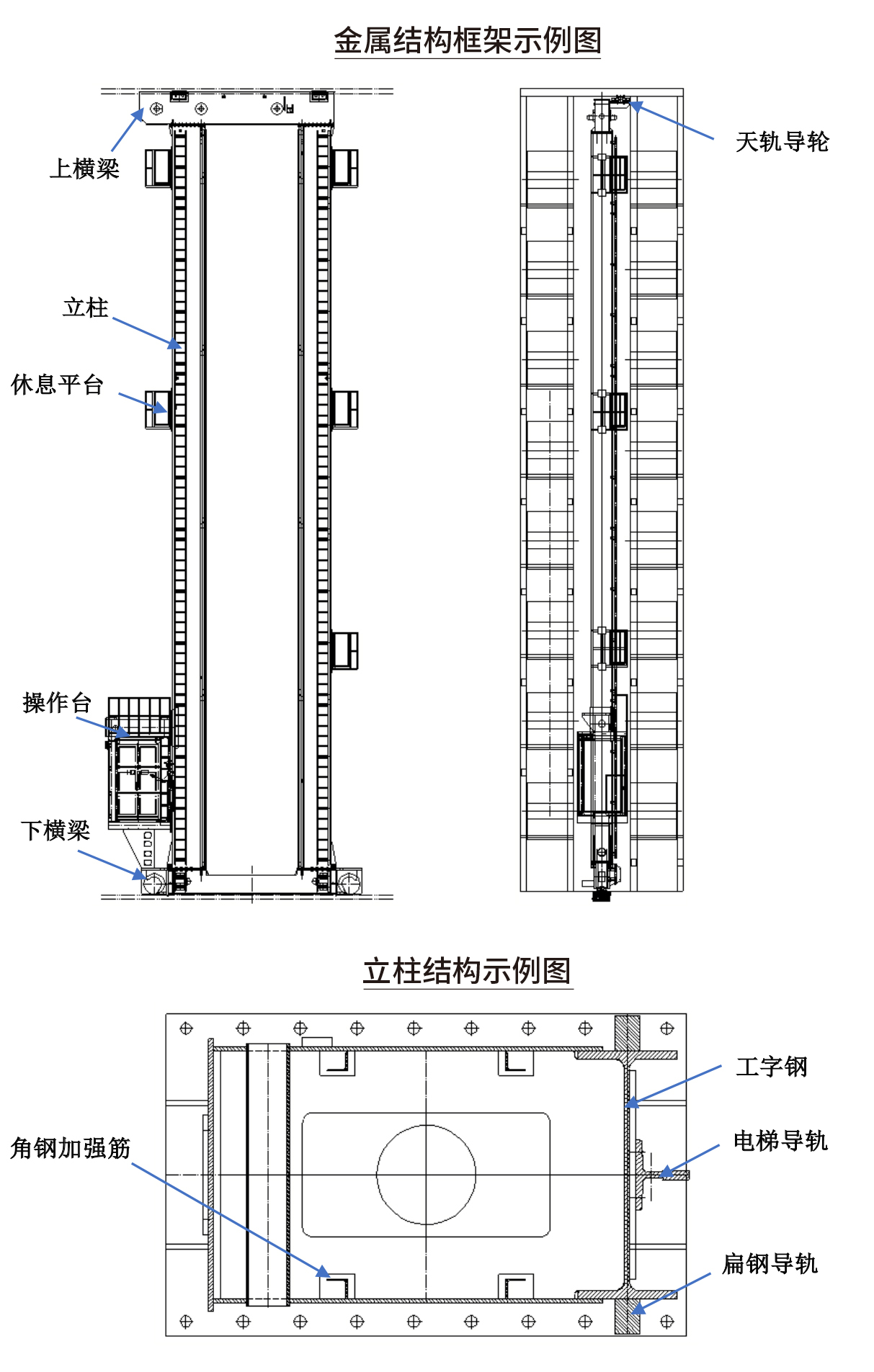

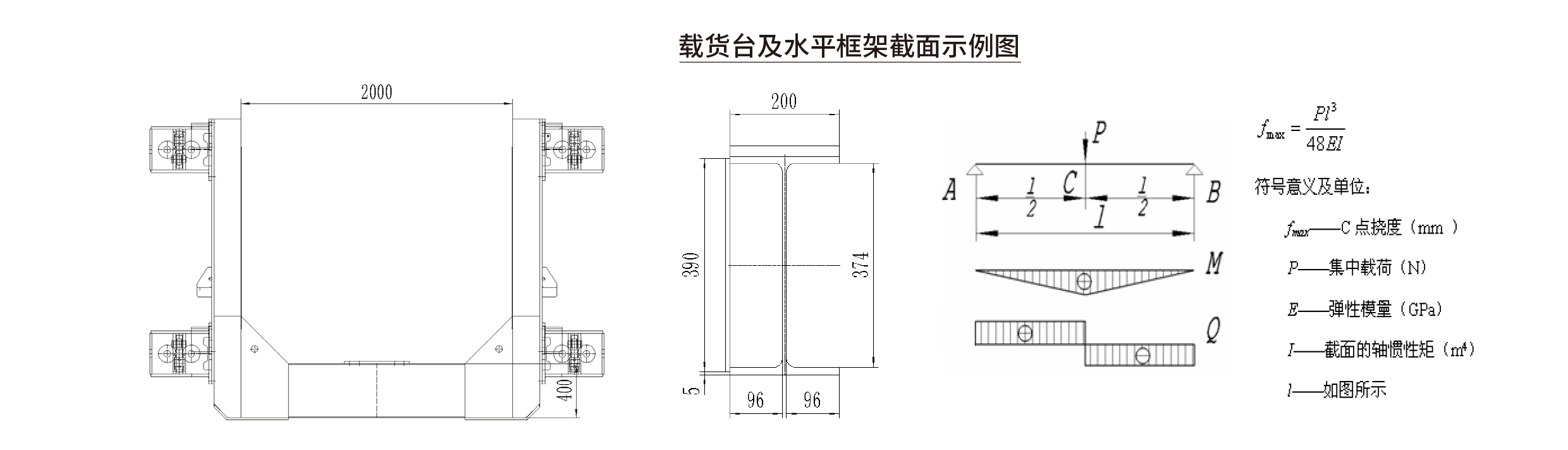

The stacker mast needs to be specially made and adopts tailor-welding method. The inner side of the stacker uses I-beam as the main bearing, and the outer side of the stacker is welded with flat steel for the running guide of the carriage.

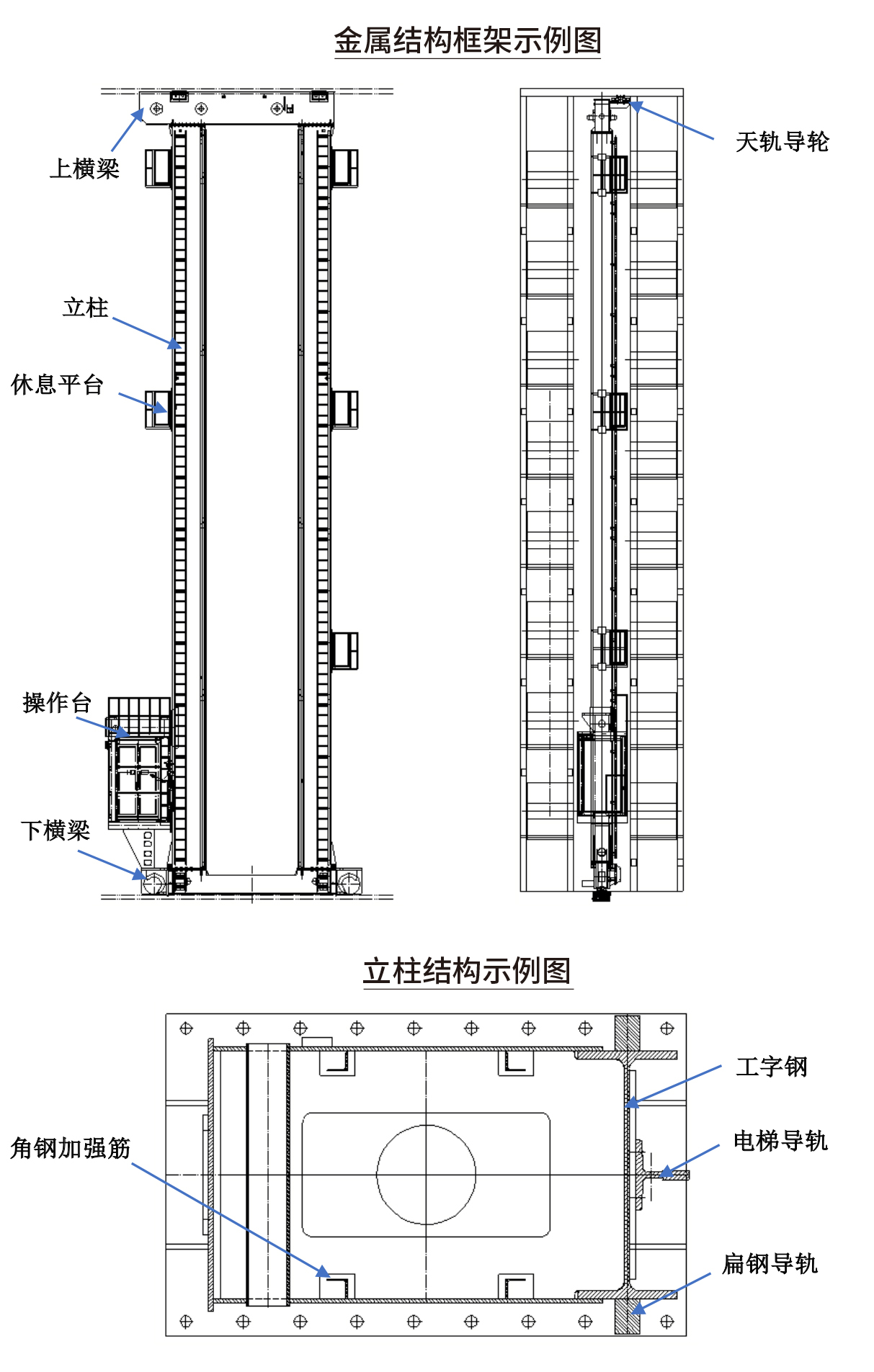

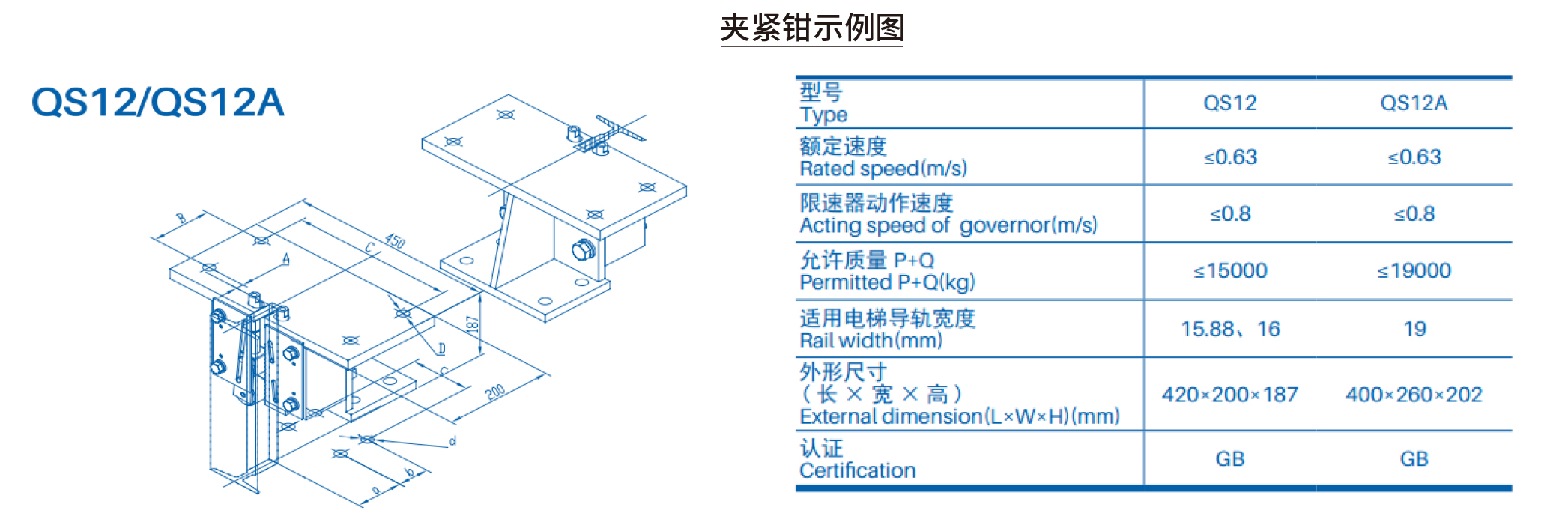

The structure of the carriage is designed with a clamping clamp protection device, and the lower beam is provided with an overspeed protection ratchet. When the wire rope is broken, the carriage falls down at an overspeed, and the ratchet brakes after reaching a certain speed, thereby driving the carriage clamping mechanism to start. The clamping clamps on both sides of the carriage are firmly clamped on the running guide rail through the flexible shaft, so that the carriage can be decelerated and braked.

The structure of the carriage is designed with a clamping clamp protection device, and the lower beam is provided with an overspeed protection ratchet. When the wire rope is broken, the carriage falls down at an overspeed, and the ratchet brakes after reaching a certain speed, thereby driving the carriage clamping mechanism to start. The clamping clamps on both sides of the carriage are firmly clamped on the running guide rail through the flexible shaft, so that the carriage can be decelerated and braked.

In the selection of the position detection device system, reliable laser ranging and address recognition are used for position determination, and the positioning accuracy can reach ±3mm. For cargo, the cargo position detection device is equipped with multiple sets of sensors such as ultrahigh, super-wide, collapsed shape, and cargo detection. It enables the equipment to have most of the functions of the stacker.

With the gradual saturation of the demand for conventional stereoscopic warehouses, traditional stackers can no longer fully meet the needs of modern industrial development, and the demand for special models of stackers in special industry markets is increasing. We have conducted a large number of tests to verify the reliability of the mechanical structure design of this model and the pick-up guide frame scheme, and have been successfully used in project examples, which can effectively improve the efficiency of coil access, reduce labor costs and warehouse space, to achieve efficient and intelligent management.

Academic Innovation Recognized Again | ROBO Proposes Design of Heavy-Load Coil Stacker

- Categories:News

- Author:

- Origin:

- Time of issue:2022-03-29 17:06

- Views:

(Summary description)

Academic Innovation Recognized Again | ROBO Proposes Design of Heavy-Load Coil Stacker

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2022-03-29 17:06

- Views:

Recently, the academic paper "Design of Heavy-load Coil Stacker" written by the mechanical design and R&D experts of the ROBO Engineering Center was successfully included in the industry authoritative academic journal "Logistics Technology and Application", directly attacking the pain points of industrial application with advanced academic achievements , once again confirming that ROBO's innovative ability in the non-standard design of core equipment stackers has been recognized by academic authorities, leading intelligent logistics with strength.

Innovation begins with demand

Grasping the real needs and development trends of customer scenarios is the core driving force of ROBO technology research and development. This paper fully demonstrates this differentiated competitive advantage, and proposes an innovative research and development demonstration of a stacker for transporting heavy-load coiled goods in a non-standard logistics scenario. Aiming at the characteristics that coiled goods cannot be accessed by conventional pallets in traditional logistics scenarios, and metal coils and paper rolls are prone to deformation and damage when they are pressed, a special guide frame mechanism is designed to fix the coiled goods. The type fork can prevent the roll material from moving and rolling, so that the goods can be stored more stably and perfectly fill the market gap.

Upgrading of academic enabling products

Due to the heavy and large size of the goods carried in the heavy-load logistics scenario, in order to improve the safety and stability of the stacker during high-speed operation, we put forward the following design arguments in terms of mechanical structure.

The stacker mast needs to be specially made and adopts tailor-welding method. The inner side of the stacker uses I-beam as the main bearing, and the outer side of the stacker is welded with flat steel for the running guide of the carriage.

The structure of the carriage is designed with a clamping clamp protection device, and the lower beam is provided with an overspeed protection ratchet. When the wire rope is broken, the carriage falls down at an overspeed, and the ratchet brakes after reaching a certain speed, thereby driving the carriage clamping mechanism to start. The clamping clamps on both sides of the carriage are firmly clamped on the running guide rail through the flexible shaft, so that the carriage can be decelerated and braked.

The structure of the carriage is designed with a clamping clamp protection device, and the lower beam is provided with an overspeed protection ratchet. When the wire rope is broken, the carriage falls down at an overspeed, and the ratchet brakes after reaching a certain speed, thereby driving the carriage clamping mechanism to start. The clamping clamps on both sides of the carriage are firmly clamped on the running guide rail through the flexible shaft, so that the carriage can be decelerated and braked.

In the selection of the position detection device system, reliable laser ranging and address recognition are used for position determination, and the positioning accuracy can reach ±3mm. For cargo, the cargo position detection device is equipped with multiple sets of sensors such as ultrahigh, super-wide, collapsed shape, and cargo detection. It enables the equipment to have most of the functions of the stacker.

With the gradual saturation of the demand for conventional stereoscopic warehouses, traditional stackers can no longer fully meet the needs of modern industrial development, and the demand for special models of stackers in special industry markets is increasing. We have conducted a large number of tests to verify the reliability of the mechanical structure design of this model and the pick-up guide frame scheme, and have been successfully used in project examples, which can effectively improve the efficiency of coil access, reduce labor costs and warehouse space, to achieve efficient and intelligent management.