Root in China, connect the world, and embrace the future together

Company News | 2021-09-08 17:10 Page views:

Interview with Deng Junting, Director of the First Engineering Center of Robo Technologies Automation (Suzhou) Co., Ltd.

Challenges come one after another, demand is overwhelming

“Keep improving, stick to our original heart.” Deng Junting, director of the First Engineering Center of ROBO Technologies Automation (Suzhou) Co., Ltd., said with emotion when looking back company development over the years, “Only operating with crisis awareness can we stand firmly and go long-term in the unpredictable market.

Dual influence of COVID-19 and shortage of chips

These words are particularly relevant in the context of 2020. Under the shadow of Covid-19, global economic activities were temporarily suspended. With strong epidemic control measures, China blowed a horn for revival in the next half of 2020, and the shortage of chips has become a barrier for manufacturing industries to move to a new level. For China's logistics equipment industry, all this will ultimately be transformed into a pressure and challenge centered on "delivery". "In the previous, the equipment could not enter the site or construction, now the problem it the shortage of production capacity." Deng explained. At the same time, the increasingly fierce competition in the market and the segmentation of the field, coupled with the more obvious head effect, are also affecting every participant in the market.

Burst of manufacturing demand

On the other hand, new market demands are continuously being expanded. Since China undertakes the role of world manufacturing center, bind up with the support of national strategies and policies and request of “steady operation”, requirements of logistics automation in the manufacturing industries starts booming. Deng explained further, “The demand of New energy, papermaking, petrochemicals, etc., industries is increasing, and working environment is comparatively serious. “Non-humanization”and delivery period becomes relatively urgent under the compact of pandemic. Besides, the border of Internet is extending to production line, “Faster and taller” has became a typical feature of logistics automation.

Concentrating advantage field, forge high quality product

ROBO believes that the emergence of the market head effect and the segmentation of the market means that the threshold and barriers of the company in its own advantageous areas are beginning to highlight. Because of key components production capacity shortage, enterprises delivery ability face trap, quick delivery becomes difficult. New birth of requirement means innovation of new technology and service mode. The ultimate core is how companies can create excellent products and services through their own supply chain operations under a certain market position to meet these needs and challenges.

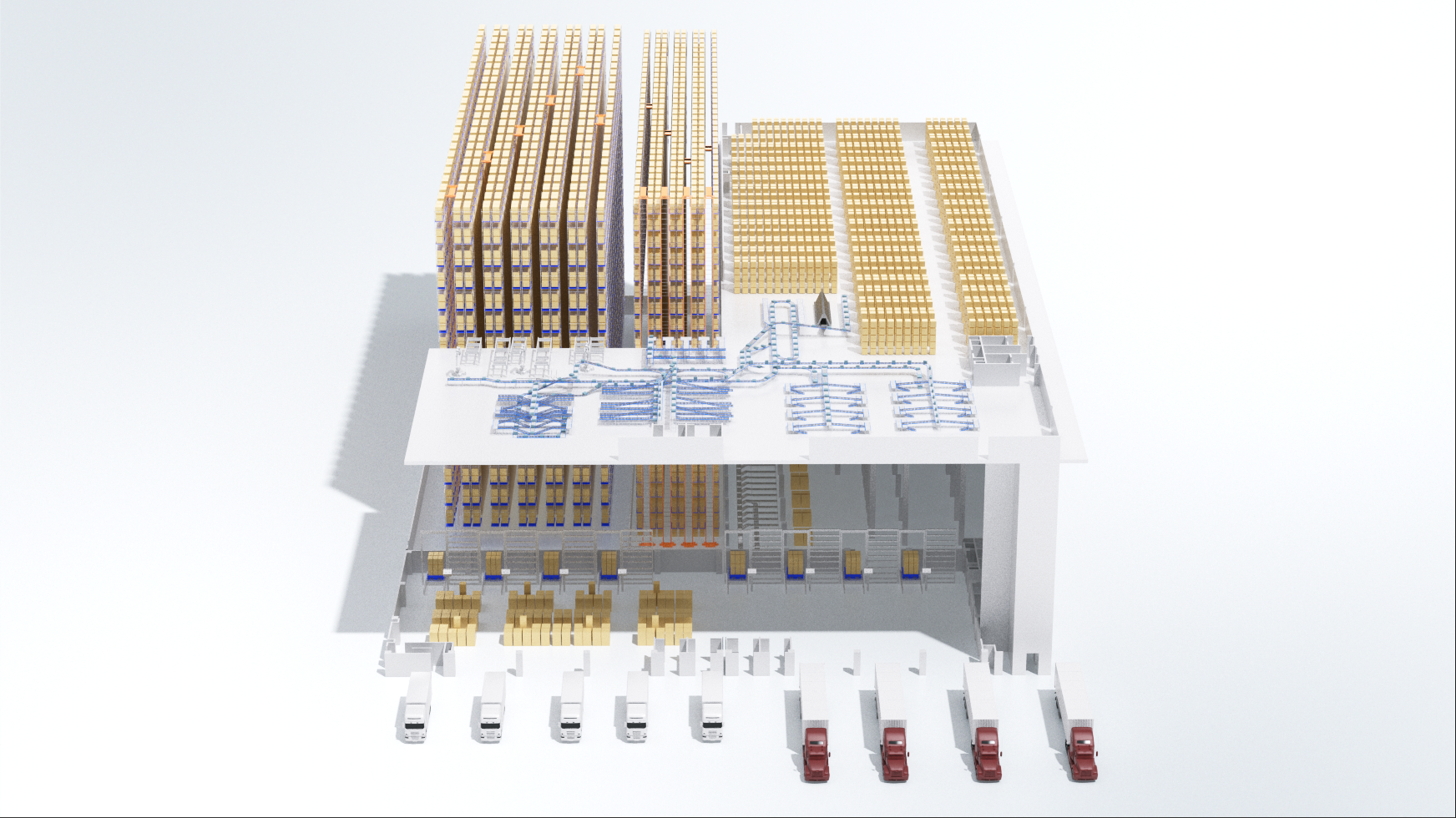

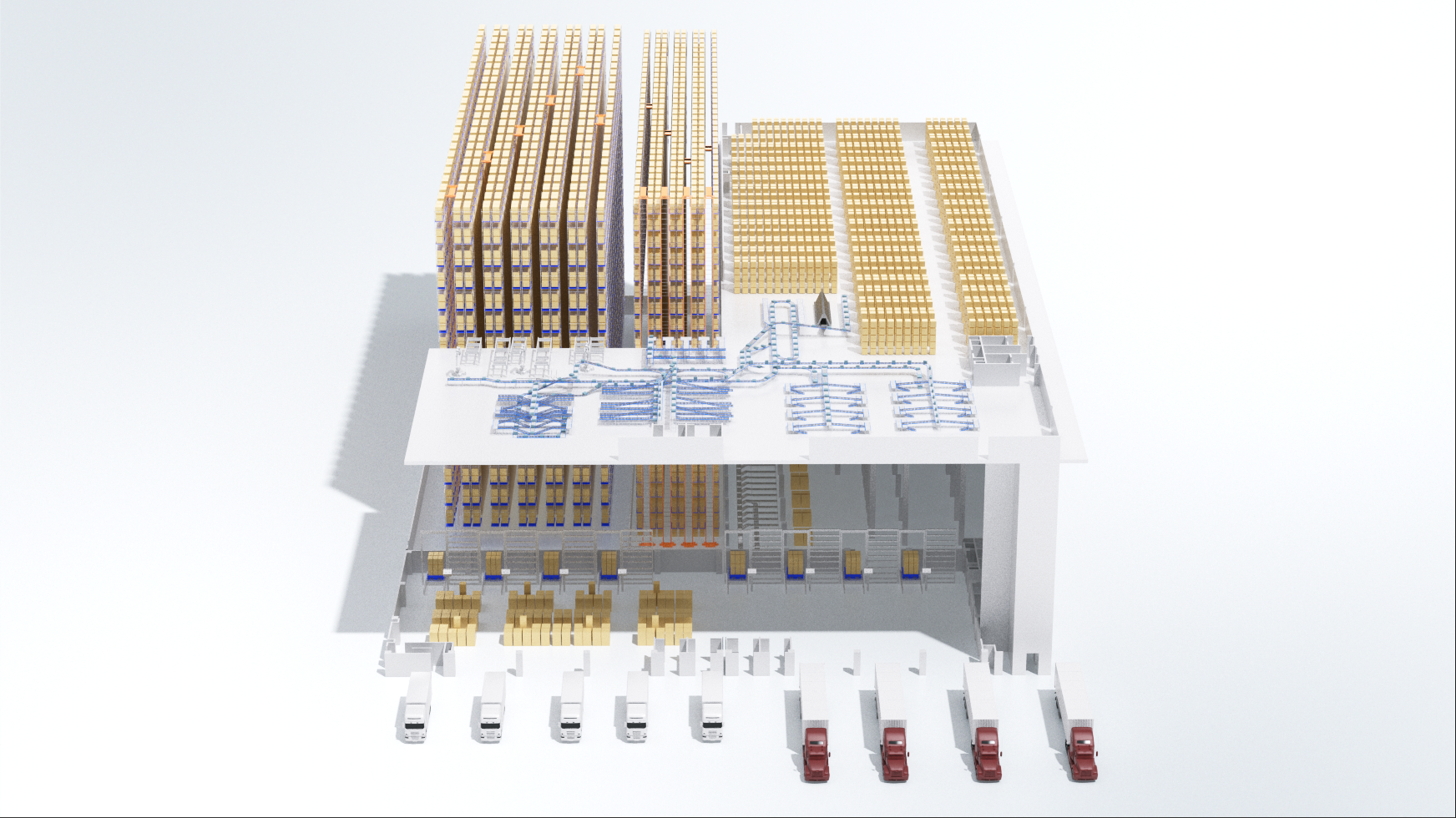

“Positioning of ROBO has never been changed all the time.” Deng said, “We concentrate on providing clients with logistics integration services mainly of stackers, multi-shuttle, etc., core equipment. And create value for customers. Bases on this positioning, ROBO actively collect and list clients’ new requirements. Conducting design and demonstration, then confirm that ROBO has equipped with whole industrial series production line. Meanwhile, cultivating the forward-looking in technical aspect.

Innovative products based on customer needs

For example, ROBO’s Giraffe series stacker products foresee the future needs of customers for land utilization and operational efficiency. Therefore, they are developing and designing the goal of up to 46m and an operating speed of 240m/min. It is understood that Giraffe series products can also be designed to drive on a turning track, which greatly improves the cost-effectiveness of the customer's investment.

Moreover, under the intelligence trend, the main point for ROBO is combine the intelligence and traditional stackers to create more value for customers. For example, according to the working pain point that the automation storage and retrieval device will be stopped working after products catch fire. ROBO designed stackers that can be continued to operate even if the cargo position catches a fire, which won the recognition of clients. Furthermore, ROBO has also developed corresponding products for the requirements of inventory check, inaccurate positioning caused by ground subsidence, and dust in dust-free occasions.

Ensure high reliability and stability

Deng focused on the reliability and stability of the product. Stacker technology has experienced 40 years of development in China. While the technology is mature and the industry is flourishing, which also brings customers "allodoxaphobia", and reliability and stability are key indicators to eliminate customers' "allodoxaphobia". In this regard, Deng said that ROBO has rich experience in industry applications, abandoning the common "discretization" design process in the industry, and constantly solidifying product module designs and applying them to different product series, so as to solve the different needs of different scenarios. At the same time, the problems and pain points encountered in the process of serving customers will also be optimized in the design to form a more stable and reliable product. It is understood that the failure rate of the entire range of ROBO products is currently controlled within 0.5%. Even ROBO has adopted a modular design in terms of materials. Through the high reuse rate of materials, it not only meets the needs of quick response to customers, but also ensures stability and reliability.

The malfunctions generated in site operation process is very complicated. Because of system or device or maybe construction technique that can not be lumped together.” Deng supplemented, ROBO promise to clients that provide stable reliable system and devices, complete malfunctions recovery rapidly through module mechanism.

Shape professional services, create value for customers

Create a service system from the perspective of “supply chain”, treat clients as families

For ROBO, “customer-centric” is not only limited to cooperate with clients o but also extend to the supply chains of enterprise itself. Deng explained, it seems that “Difficult delivery” is a challenge for service level, but is actually test enterprises’ coordinate between upstream and downstream of supply chains. “In deed, ROBO also face the shortage of chips, but we run supply chains with heart all the time, and treat upstream suppliers and downstream clients as “Families”, so as to create win-win in supply chains. “Based on this service philosophy, ROBO’s suppliers even transfer goods from friends at a market price three times higher than the normal price, and supply ROBO at parity.

The same is true for ROBO’s services to customers. We will do our best to meet all reasonable needs of customers, especially for some emerging industries and special requirements such as ultra-high and overweight. Communicate fully until they are satisfied. At the same time, ROBO has developed a cloud platform, which has changed the passive inspection and maintenance strategy in the past, and has taken the initiative to ensure the operation of customers better. Moreover, in order to improve the response speed of customers, ROBO actively introduces intelligent manufacturing, and reduces the delivery time of the project through intelligent technologies such as digital twins. According to Deng, after using intelligent manufacturing technology, the project duration can be saved by at least 30%, while also saving a lot of manpower and marginal costs.

Localization to meet local needs

"Localization" is a common strategy of international companies, and ROBO also has his own understanding of this. Deng firmly stated that localization is not simply to take foreign drawings and technologies to the local market for re-engraving, but should combine the local humanities and technology to rebuild the team after reconstruction. Taking localized production as an example, ROBO took into account the gap between China and Austria in the production process level, so the production technique and process were reshaped to ensure that the products produced in China can achieve the same reliability and stability. "The goal of localization should not be just to reduce costs." Deng said seriously, "Each market has its own special needs and restrictions. Localization should address the special needs of the local market on top of the general needs. Such local transformation can bring benefits to the development of the global market."

In fact, such a localization strategy has provided a lot of help for ROBO’s global success, especially under the epidemic. ROBO’s development in the Chinese market and the experience of overcoming challenges have offered excellent development experience to other countries and regions all over the world.

In China, for China, and the world

"In China, for China, and the world. It is our corporate culture and our business philosophy." Deng said proudly, "Under the influence of such a culture, we are committed to creating value for our customers and ensuring reasonable profit of our partners. This is the basis for us to provide stable and reliable services for our customers."

In order to practice such a culture, ROBO established a very high entry barrier at the beginning of the team building, and established an excellent talent training and promotion mechanism. "The employees may not stay with us forever, but we can let our corporate culture been deeply rooted in the hearts of the everyone. No matter where our employees are, they will be proud of ROBO." Deng continued, "Since the establishment of the team, every employee is edified under the spirit oof struggle and sense of responsibility. We fully respected for their labor achievements."

Speaking of the future, Deng believes that "diversification" is an inevitable trend in the future, especially as the number of new companies exposed with new industries will increase, and they will focus more and more on their own areas of advantage, which will also help form a better business environment for China's logistics equipment market. For ROBO, sticking to its own positioning and continuing to create value and win-win situation for customers and partners is its unchanging original intention. In the end, Deng said: “Operating business of logistics equipment will neither make you rich quickly nor lose all at once. The right way is to work with painstaking efforts, strive for perfection, and create more value for the industry.

Root in China, connect the world, and embrace the future together

- Categories:News

- Author:

- Origin:

- Time of issue:2021-09-08 17:10

- Views:

(Summary description)

Root in China, connect the world, and embrace the future together

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2021-09-08 17:10

- Views:

Interview with Deng Junting, Director of the First Engineering Center of Robo Technologies Automation (Suzhou) Co., Ltd.

Challenges come one after another, demand is overwhelming

“Keep improving, stick to our original heart.” Deng Junting, director of the First Engineering Center of ROBO Technologies Automation (Suzhou) Co., Ltd., said with emotion when looking back company development over the years, “Only operating with crisis awareness can we stand firmly and go long-term in the unpredictable market.

Dual influence of COVID-19 and shortage of chips

These words are particularly relevant in the context of 2020. Under the shadow of Covid-19, global economic activities were temporarily suspended. With strong epidemic control measures, China blowed a horn for revival in the next half of 2020, and the shortage of chips has become a barrier for manufacturing industries to move to a new level. For China's logistics equipment industry, all this will ultimately be transformed into a pressure and challenge centered on "delivery". "In the previous, the equipment could not enter the site or construction, now the problem it the shortage of production capacity." Deng explained. At the same time, the increasingly fierce competition in the market and the segmentation of the field, coupled with the more obvious head effect, are also affecting every participant in the market.

Burst of manufacturing demand

On the other hand, new market demands are continuously being expanded. Since China undertakes the role of world manufacturing center, bind up with the support of national strategies and policies and request of “steady operation”, requirements of logistics automation in the manufacturing industries starts booming. Deng explained further, “The demand of New energy, papermaking, petrochemicals, etc., industries is increasing, and working environment is comparatively serious. “Non-humanization”and delivery period becomes relatively urgent under the compact of pandemic. Besides, the border of Internet is extending to production line, “Faster and taller” has became a typical feature of logistics automation.

Concentrating advantage field, forge high quality product

ROBO believes that the emergence of the market head effect and the segmentation of the market means that the threshold and barriers of the company in its own advantageous areas are beginning to highlight. Because of key components production capacity shortage, enterprises delivery ability face trap, quick delivery becomes difficult. New birth of requirement means innovation of new technology and service mode. The ultimate core is how companies can create excellent products and services through their own supply chain operations under a certain market position to meet these needs and challenges.

“Positioning of ROBO has never been changed all the time.” Deng said, “We concentrate on providing clients with logistics integration services mainly of stackers, multi-shuttle, etc., core equipment. And create value for customers. Bases on this positioning, ROBO actively collect and list clients’ new requirements. Conducting design and demonstration, then confirm that ROBO has equipped with whole industrial series production line. Meanwhile, cultivating the forward-looking in technical aspect.

Innovative products based on customer needs

For example, ROBO’s Giraffe series stacker products foresee the future needs of customers for land utilization and operational efficiency. Therefore, they are developing and designing the goal of up to 46m and an operating speed of 240m/min. It is understood that Giraffe series products can also be designed to drive on a turning track, which greatly improves the cost-effectiveness of the customer's investment.

Moreover, under the intelligence trend, the main point for ROBO is combine the intelligence and traditional stackers to create more value for customers. For example, according to the working pain point that the automation storage and retrieval device will be stopped working after products catch fire. ROBO designed stackers that can be continued to operate even if the cargo position catches a fire, which won the recognition of clients. Furthermore, ROBO has also developed corresponding products for the requirements of inventory check, inaccurate positioning caused by ground subsidence, and dust in dust-free occasions.

Ensure high reliability and stability

Deng focused on the reliability and stability of the product. Stacker technology has experienced 40 years of development in China. While the technology is mature and the industry is flourishing, which also brings customers "allodoxaphobia", and reliability and stability are key indicators to eliminate customers' "allodoxaphobia". In this regard, Deng said that ROBO has rich experience in industry applications, abandoning the common "discretization" design process in the industry, and constantly solidifying product module designs and applying them to different product series, so as to solve the different needs of different scenarios. At the same time, the problems and pain points encountered in the process of serving customers will also be optimized in the design to form a more stable and reliable product. It is understood that the failure rate of the entire range of ROBO products is currently controlled within 0.5%. Even ROBO has adopted a modular design in terms of materials. Through the high reuse rate of materials, it not only meets the needs of quick response to customers, but also ensures stability and reliability.

The malfunctions generated in site operation process is very complicated. Because of system or device or maybe construction technique that can not be lumped together.” Deng supplemented, ROBO promise to clients that provide stable reliable system and devices, complete malfunctions recovery rapidly through module mechanism.

Shape professional services, create value for customers

Create a service system from the perspective of “supply chain”, treat clients as families

For ROBO, “customer-centric” is not only limited to cooperate with clients o but also extend to the supply chains of enterprise itself. Deng explained, it seems that “Difficult delivery” is a challenge for service level, but is actually test enterprises’ coordinate between upstream and downstream of supply chains. “In deed, ROBO also face the shortage of chips, but we run supply chains with heart all the time, and treat upstream suppliers and downstream clients as “Families”, so as to create win-win in supply chains. “Based on this service philosophy, ROBO’s suppliers even transfer goods from friends at a market price three times higher than the normal price, and supply ROBO at parity.

The same is true for ROBO’s services to customers. We will do our best to meet all reasonable needs of customers, especially for some emerging industries and special requirements such as ultra-high and overweight. Communicate fully until they are satisfied. At the same time, ROBO has developed a cloud platform, which has changed the passive inspection and maintenance strategy in the past, and has taken the initiative to ensure the operation of customers better. Moreover, in order to improve the response speed of customers, ROBO actively introduces intelligent manufacturing, and reduces the delivery time of the project through intelligent technologies such as digital twins. According to Deng, after using intelligent manufacturing technology, the project duration can be saved by at least 30%, while also saving a lot of manpower and marginal costs.

Localization to meet local needs

"Localization" is a common strategy of international companies, and ROBO also has his own understanding of this. Deng firmly stated that localization is not simply to take foreign drawings and technologies to the local market for re-engraving, but should combine the local humanities and technology to rebuild the team after reconstruction. Taking localized production as an example, ROBO took into account the gap between China and Austria in the production process level, so the production technique and process were reshaped to ensure that the products produced in China can achieve the same reliability and stability. "The goal of localization should not be just to reduce costs." Deng said seriously, "Each market has its own special needs and restrictions. Localization should address the special needs of the local market on top of the general needs. Such local transformation can bring benefits to the development of the global market."

In fact, such a localization strategy has provided a lot of help for ROBO’s global success, especially under the epidemic. ROBO’s development in the Chinese market and the experience of overcoming challenges have offered excellent development experience to other countries and regions all over the world.

In China, for China, and the world

"In China, for China, and the world. It is our corporate culture and our business philosophy." Deng said proudly, "Under the influence of such a culture, we are committed to creating value for our customers and ensuring reasonable profit of our partners. This is the basis for us to provide stable and reliable services for our customers."

In order to practice such a culture, ROBO established a very high entry barrier at the beginning of the team building, and established an excellent talent training and promotion mechanism. "The employees may not stay with us forever, but we can let our corporate culture been deeply rooted in the hearts of the everyone. No matter where our employees are, they will be proud of ROBO." Deng continued, "Since the establishment of the team, every employee is edified under the spirit oof struggle and sense of responsibility. We fully respected for their labor achievements."

Speaking of the future, Deng believes that "diversification" is an inevitable trend in the future, especially as the number of new companies exposed with new industries will increase, and they will focus more and more on their own areas of advantage, which will also help form a better business environment for China's logistics equipment market. For ROBO, sticking to its own positioning and continuing to create value and win-win situation for customers and partners is its unchanging original intention. In the end, Deng said: “Operating business of logistics equipment will neither make you rich quickly nor lose all at once. The right way is to work with painstaking efforts, strive for perfection, and create more value for the industry.