Innovation Breakthrough | ROBO Proposes Design of Ultra-long Truss Stacker

Company News | 2022-02-25 15:21 Page views:

Recently, the mechanical design and research and development experts of the ROBO Engineering Center proposed the design of the industry-leading ultra-long truss stacker, showing that in the non-standard customization of the intelligent storage system, the size of the goods carried far exceeds the conventional goods such as general pallet materials. The innovative R&D demonstration of the truss-type stacker in the scenario directly hits the pain points of industrial application with advanced academic achievements. The paper has been successfully published din the industry authoritative academic journal "Logistics Technology and Application", which fully confirms that ROBO has been recognized by academic authorities in terms of innovation ability and technical strength of stacker products and equipment.

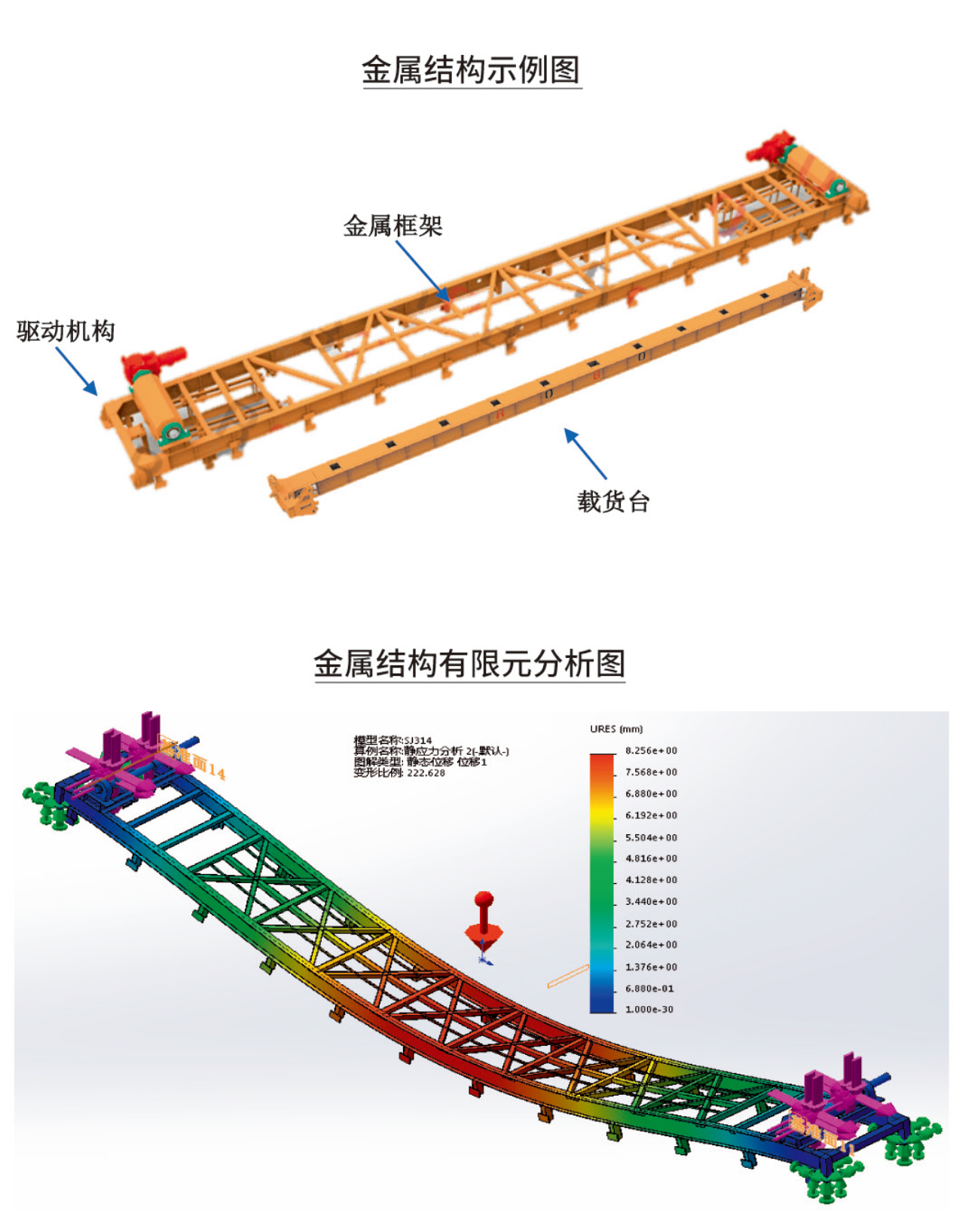

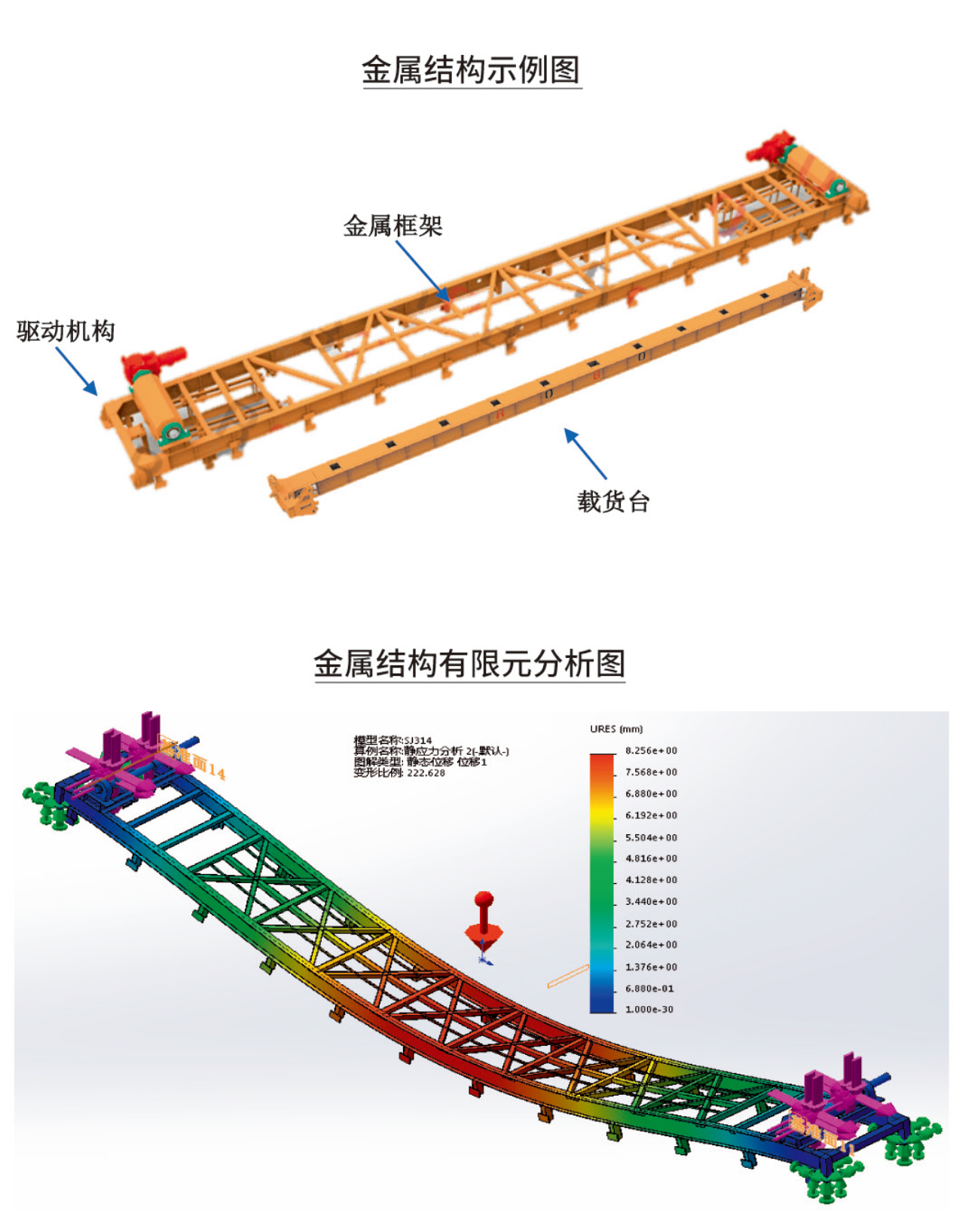

The paper mainly describes the stacker used for transporting goods between the truss-type steel structure racks. The walking direction and fork direction of such stackers are different from those of conventional stackers, and the aisle is replaced at the top of the rack, which is similar to driving, but it has the horizontal pick and place function of the stacker. The width of the metal structure of this type of stacker is very large, and the carriage is very wide, and the size of the goods it carries far exceeds that of conventional goods such as general pallet materials. This kind of goods can no longer meet the requirements of picking up goods using traditional cranes or conventional stackers. In response to these special needs, this ultra-long truss-type stacker can fully meet the requirements. On the premise of ensuring product functions, the design of the ultra-long truss-type stacker is completed, which improves the utilization rate of storage space.

Due to the special specifications of the steel pipe structure and other goods, the length is very long, which has far exceeded the size of the international pallet. Therefore, the width of the metal structure and the carriage needs to be widened, and the static load deflection of the structure is much larger than that of the conventional stacker. In response to this non-standard mechanical structure, ROBO proposed in the article that strict calculation and software analysis are required in the process of development and design, in order to ensure the rigidity of the structure and solve the problem of picking deviation and operation caused by excessive deflection.

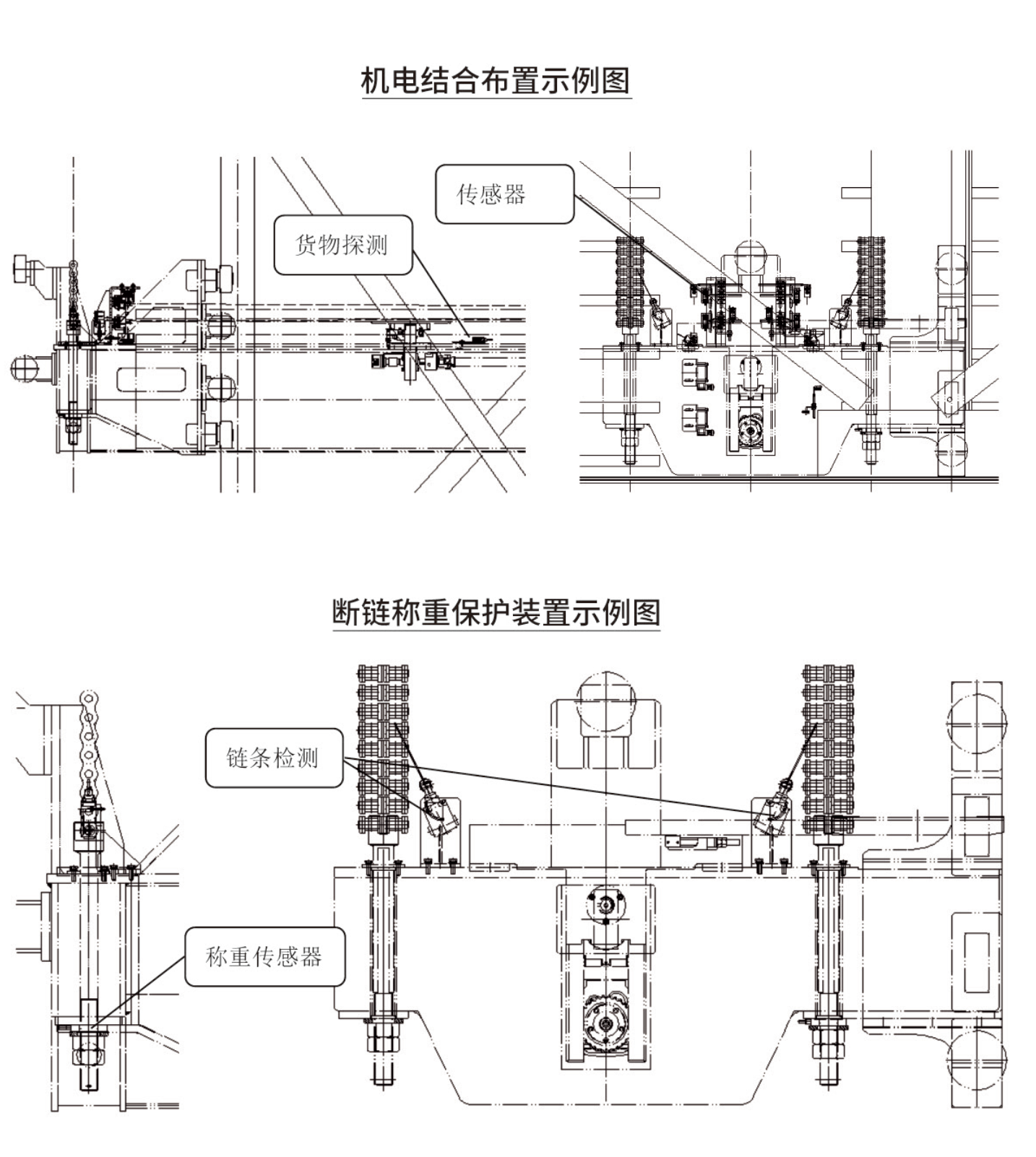

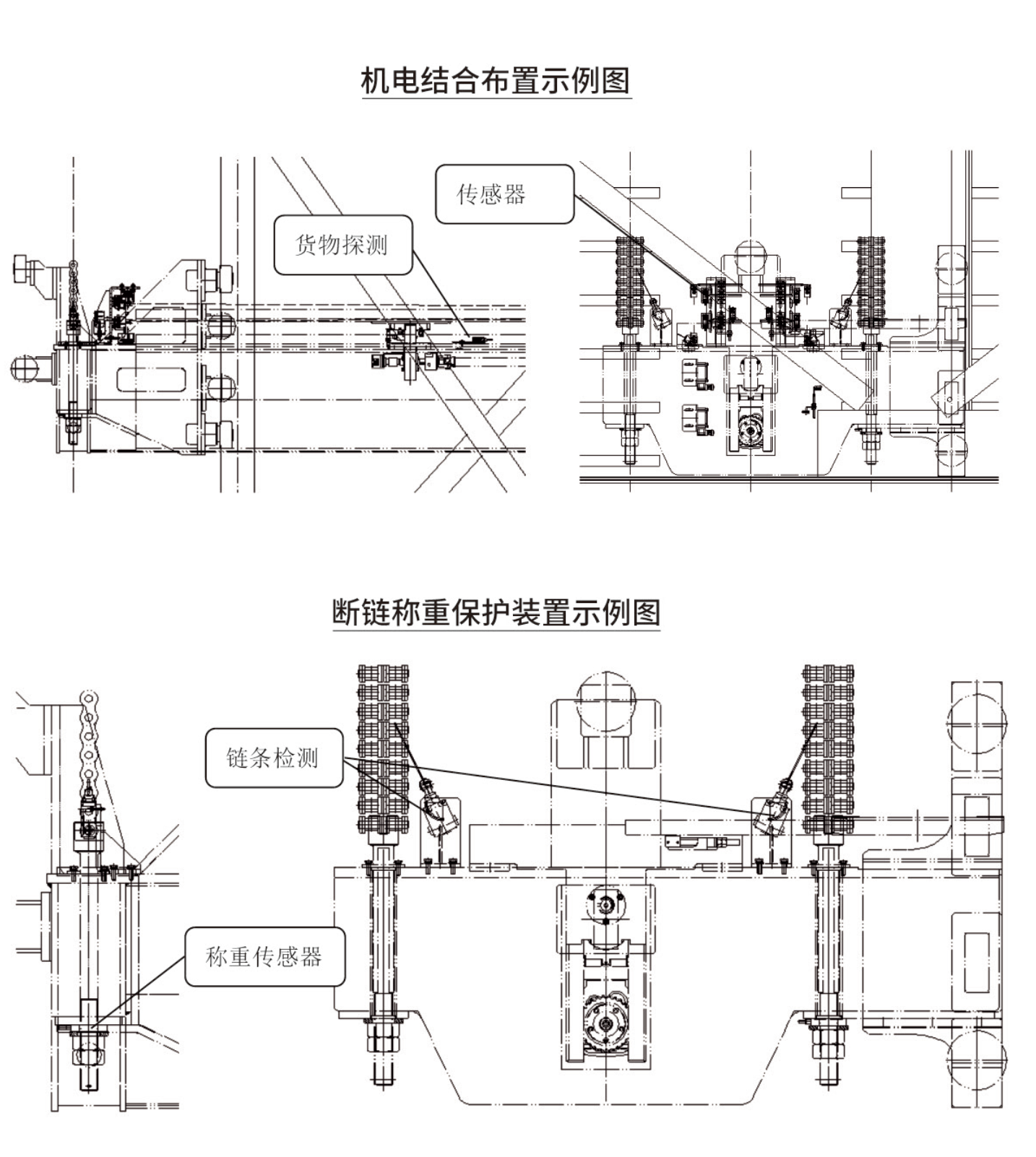

In this stacker design, reliable laser ranging and address recognition are used for position determination, and the positioning accuracy can reach ±3mm. For cargo, the cargo position detection device is equipped with multiple sets of sensors such as superelevation, super-wide, collapsed shape, and cargo detection. It enables the equipment to have most of the functions of the stacker. Not only that, this stacker also has chain break detection and weighing detection functions. It uses four detection sensors to detect the chain. When the chain breaks, the sensor alarm is triggered and the equipment stops running. A load cell is installed under the chain fixing rod. When the load quality exceeds the rated load, the load cell alarm is triggered.

With the gradual saturation of the demand for conventional stereoscopic warehouses, traditional stackers can no longer fully meet the needs of modern industrial development, and the demand for special models of stackers in special industry markets is increasing. In this paper, the method of finite element analysis and project trial production verification is adopted, considering that the truss-type stacker is affected by factors such as excessive deflection and asynchronous drive wheel deviation, and under the premise of ensuring product functions, a better rigidity and simple manufacturing process are designed. The super-long truss-type stacker can meet the needs of use and make the equipment run stably and reliably.

Innovation Breakthrough | ROBO Proposes Design of Ultra-long Truss Stacker

- Categories:News

- Author:

- Origin:

- Time of issue:2022-02-25 15:21

- Views:

(Summary description)

Innovation Breakthrough | ROBO Proposes Design of Ultra-long Truss Stacker

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2022-02-25 15:21

- Views:

Recently, the mechanical design and research and development experts of the ROBO Engineering Center proposed the design of the industry-leading ultra-long truss stacker, showing that in the non-standard customization of the intelligent storage system, the size of the goods carried far exceeds the conventional goods such as general pallet materials. The innovative R&D demonstration of the truss-type stacker in the scenario directly hits the pain points of industrial application with advanced academic achievements. The paper has been successfully published din the industry authoritative academic journal "Logistics Technology and Application", which fully confirms that ROBO has been recognized by academic authorities in terms of innovation ability and technical strength of stacker products and equipment.

The paper mainly describes the stacker used for transporting goods between the truss-type steel structure racks. The walking direction and fork direction of such stackers are different from those of conventional stackers, and the aisle is replaced at the top of the rack, which is similar to driving, but it has the horizontal pick and place function of the stacker. The width of the metal structure of this type of stacker is very large, and the carriage is very wide, and the size of the goods it carries far exceeds that of conventional goods such as general pallet materials. This kind of goods can no longer meet the requirements of picking up goods using traditional cranes or conventional stackers. In response to these special needs, this ultra-long truss-type stacker can fully meet the requirements. On the premise of ensuring product functions, the design of the ultra-long truss-type stacker is completed, which improves the utilization rate of storage space.

Due to the special specifications of the steel pipe structure and other goods, the length is very long, which has far exceeded the size of the international pallet. Therefore, the width of the metal structure and the carriage needs to be widened, and the static load deflection of the structure is much larger than that of the conventional stacker. In response to this non-standard mechanical structure, ROBO proposed in the article that strict calculation and software analysis are required in the process of development and design, in order to ensure the rigidity of the structure and solve the problem of picking deviation and operation caused by excessive deflection.

In this stacker design, reliable laser ranging and address recognition are used for position determination, and the positioning accuracy can reach ±3mm. For cargo, the cargo position detection device is equipped with multiple sets of sensors such as superelevation, super-wide, collapsed shape, and cargo detection. It enables the equipment to have most of the functions of the stacker. Not only that, this stacker also has chain break detection and weighing detection functions. It uses four detection sensors to detect the chain. When the chain breaks, the sensor alarm is triggered and the equipment stops running. A load cell is installed under the chain fixing rod. When the load quality exceeds the rated load, the load cell alarm is triggered.

With the gradual saturation of the demand for conventional stereoscopic warehouses, traditional stackers can no longer fully meet the needs of modern industrial development, and the demand for special models of stackers in special industry markets is increasing. In this paper, the method of finite element analysis and project trial production verification is adopted, considering that the truss-type stacker is affected by factors such as excessive deflection and asynchronous drive wheel deviation, and under the premise of ensuring product functions, a better rigidity and simple manufacturing process are designed. The super-long truss-type stacker can meet the needs of use and make the equipment run stably and reliably.