ROBOTECHLOG is listed among the TOP-3 global stacker crane (SRM) manufacturers, leading smart logistics with strength

Company News | 2022-09-06 09:34 Page views:

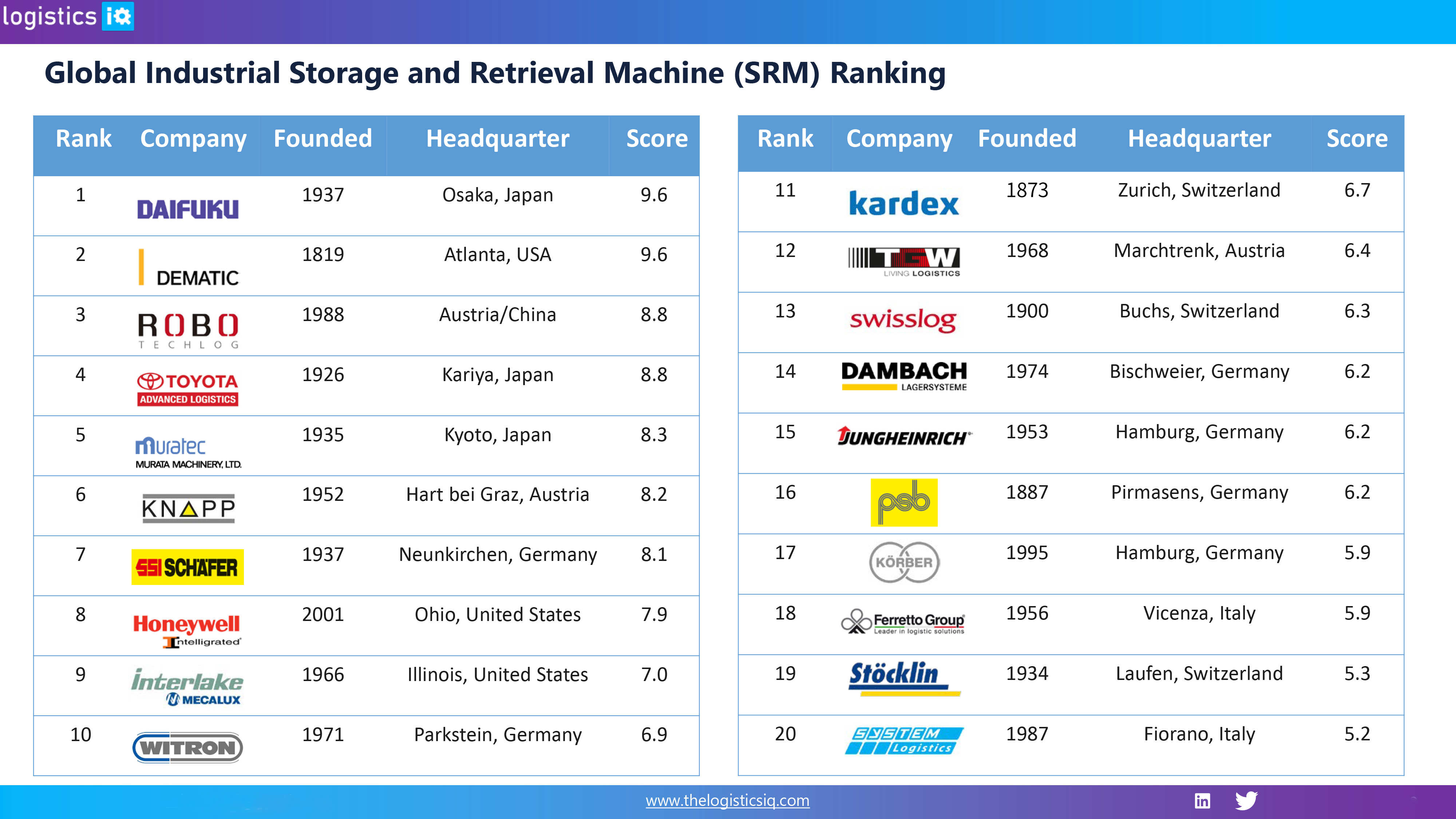

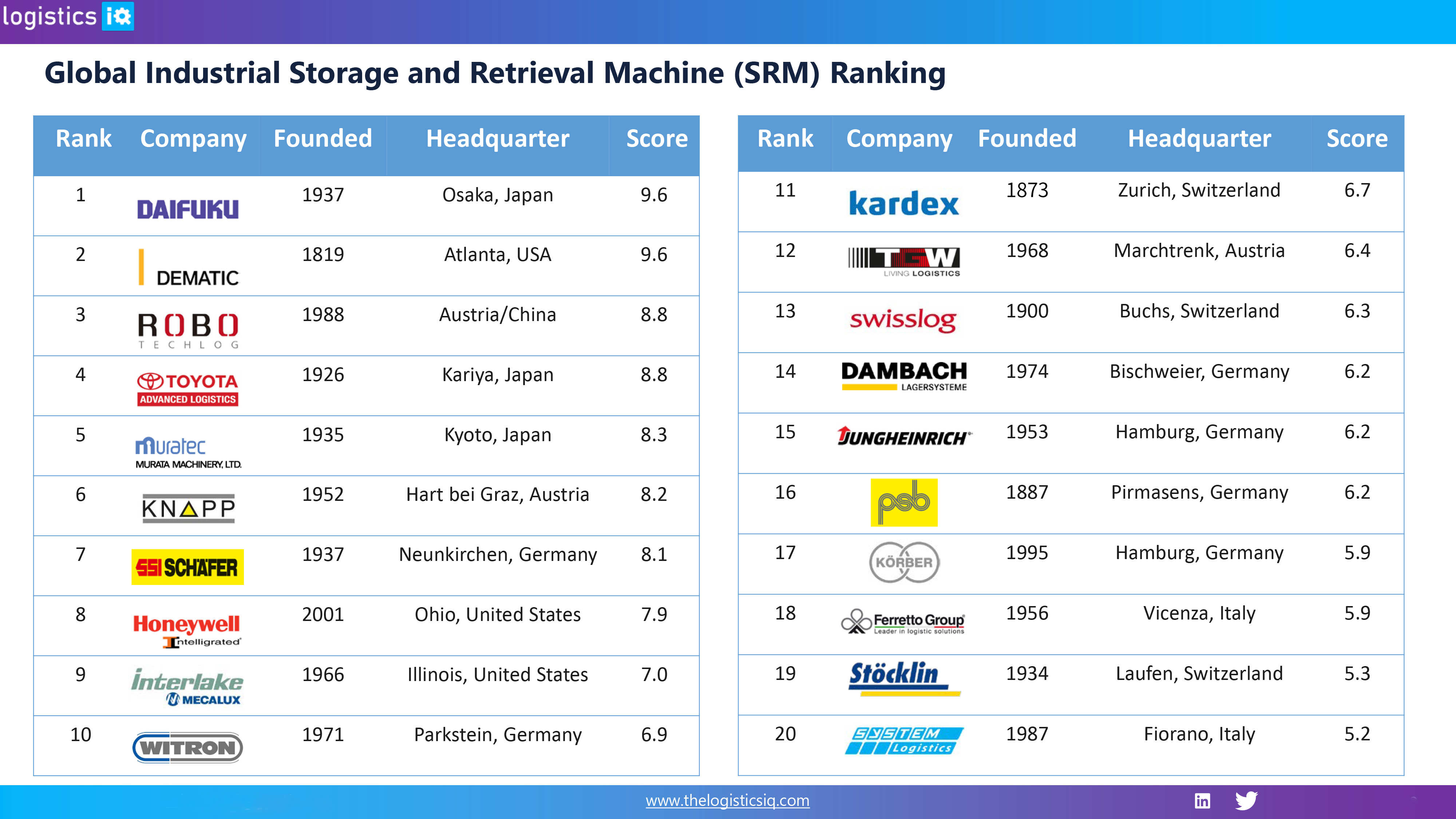

Recently, As an international authoritative logistics and supply chain research & consulting company, LogisticsIQ released the "Global Industrial SRM (Storage and Retrieval Machine) Ranking Analysis" list. With its outstanding innovation ability and technical strength, ROBOTECHLOG has won the global TOP20 stacker manufacturing enterprise. , in the Top 3.

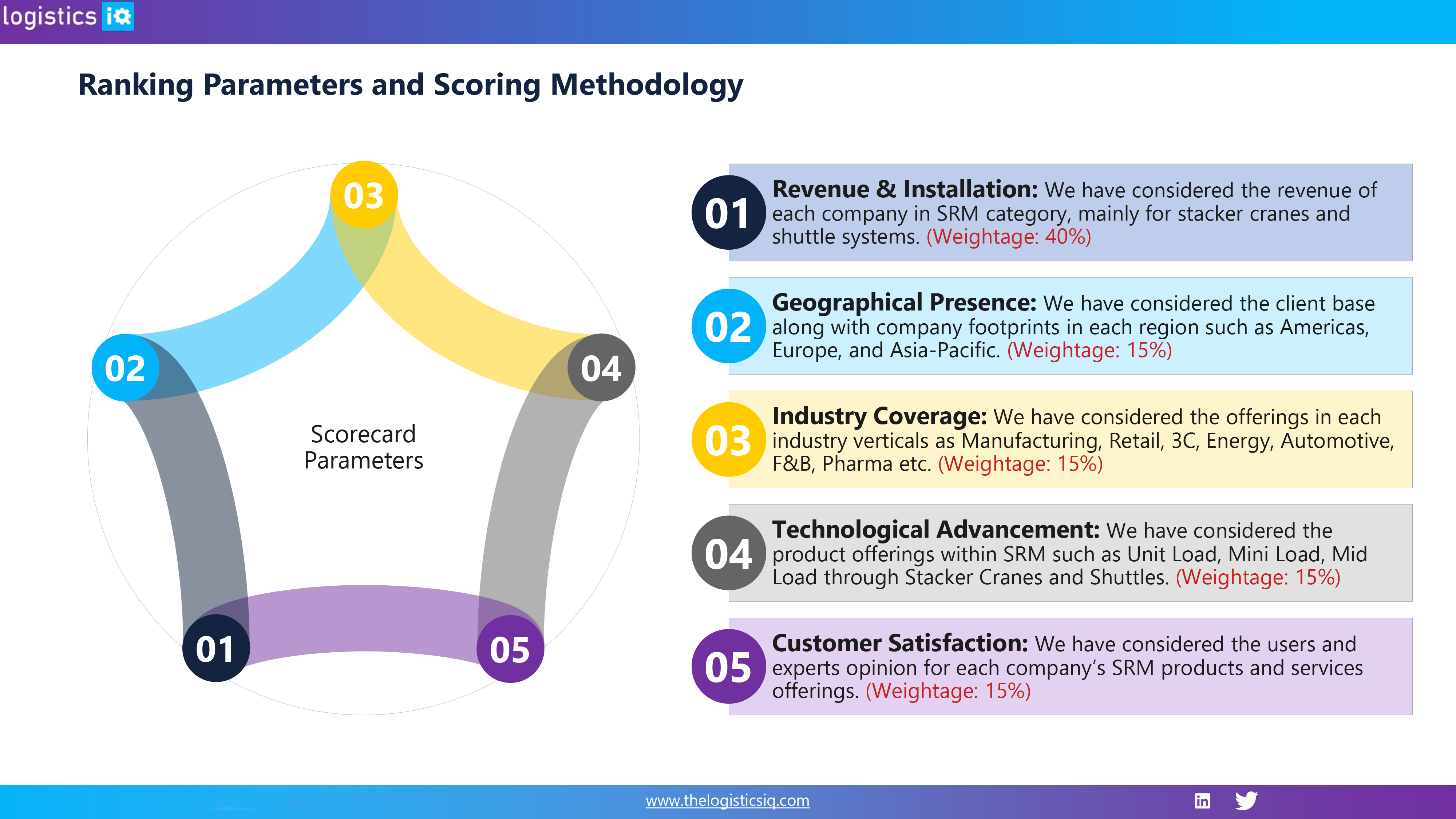

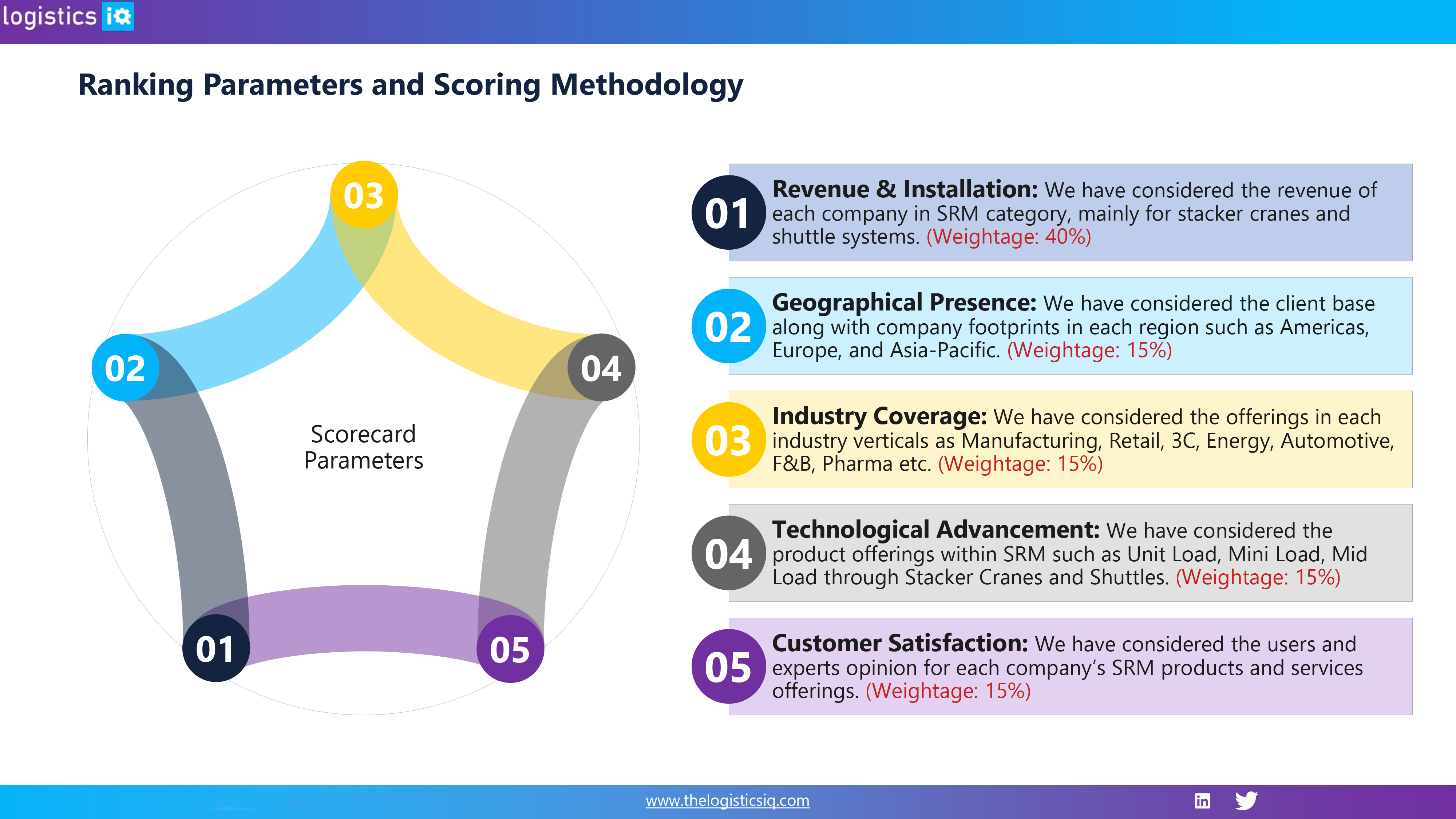

"Global Industrial SRM (Storage and Retrieval Machine) Ranking Analysis" list from Revenue & Installation, Geographical Presence, Industry Coverage, Technological Advancement, Customer Satisfaction and other multi-dimensional evaluations to select the global TOP20. The list is recognized as the vane of the development of the global automated warehousing market. According to the Logistics IQ report, SRM (Storage and Retrieval Machine) has always been the core equipment of production logistics and manufacturing storage systems. As the need for automation increased, SRM created its own space in the multi-billion dollar market for material handling equipment.

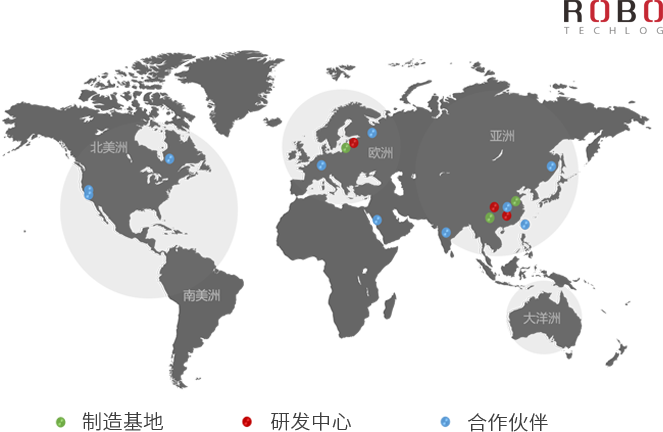

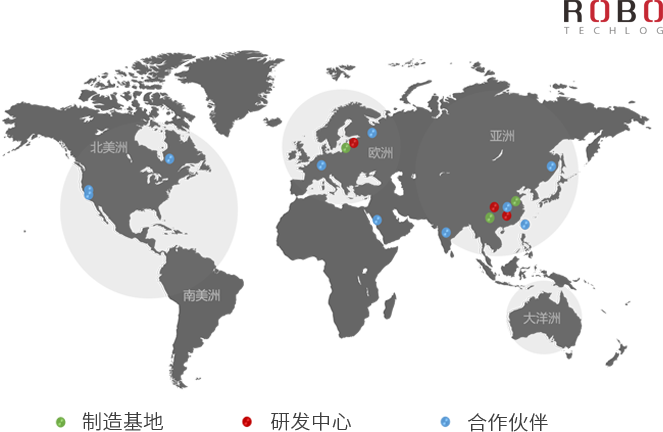

ROBOTECHLOG brand was founded in Dornbirn, Austria in 1988. In 2014, it took root in China and realized the "localization" strategy of stacker equipment, realizing team localization and product localization. As the first equipment manufacturing provider to realize large-scale and mass production of stackers in China, it has global sales, operation and service capabilities in more than 20 countries and regions around the world, and has realized industrialization for more than 100 sub-sectors Empowerment, the global equipment sales have reached 4000+ sets/sets. Became the first core equipment supplier in the industry to realize "product development、personalized customization、mechanical manufacturing、electrical implementation、software integration" in China.

Facing the rapid development of the global intelligent logistics equipment market in recent years, ROBOTECHLOG has always focused on the R&D and manufacturing of stacker products, deeply cultivated the market, launched a variety of dedicated stacker models for multiple segments, and worked with industry partners to create a variety of scenarios. Smart logistics solutions, covering new energy, optical fiber, tobacco, aviation, food and beverage, automobile, medicine, cold chain, 3C, power and other industries.

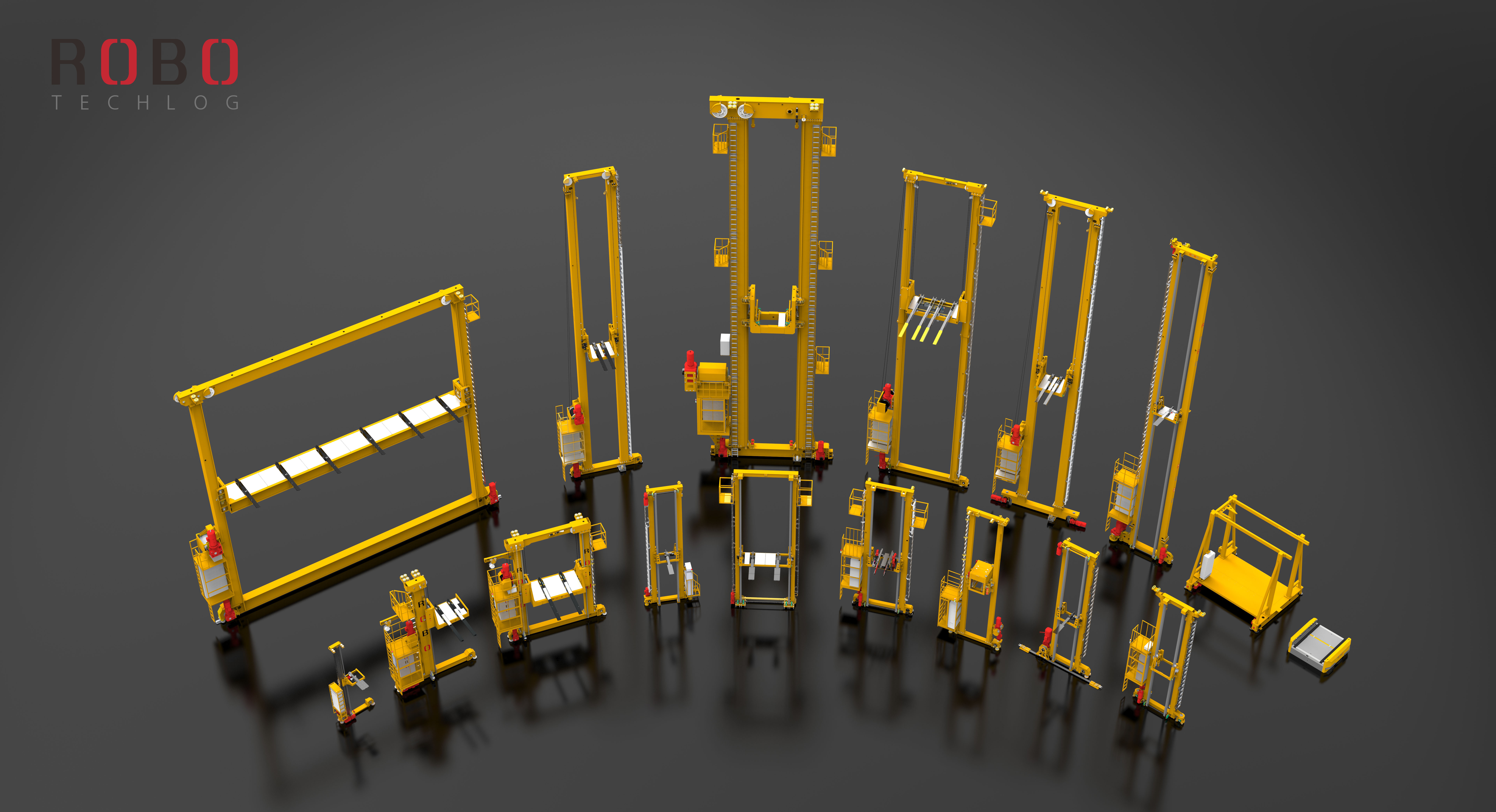

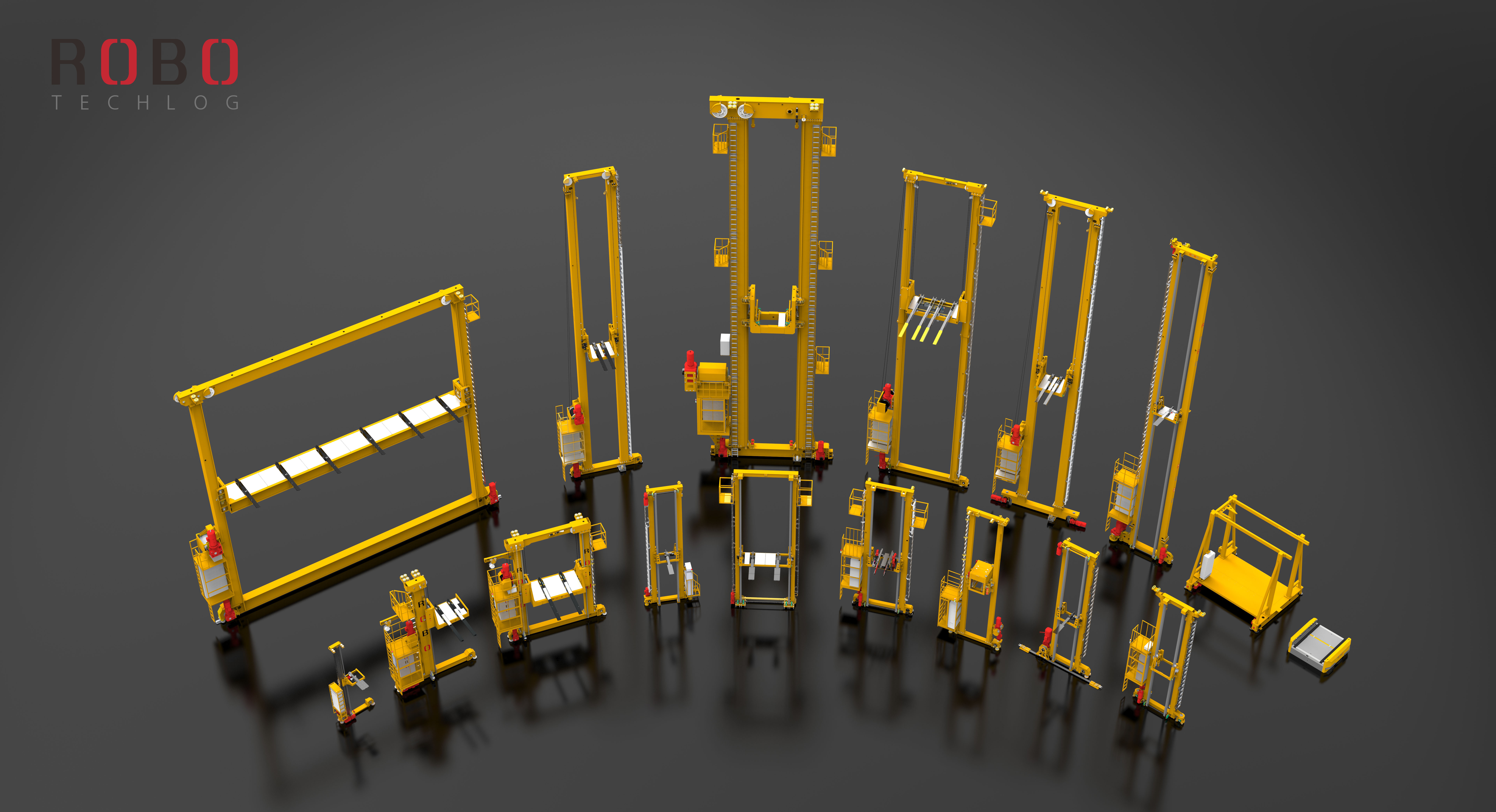

ROBOTECHLOG always adheres to the innovation point of customer demand, and continuously develops and innovates to achieve full scene coverage with all categories of products. Through 7 series of products of PANTHER, ZEBRA, CHEETAH, BULL, GIRAFFE, LION and DORADO, we can meet the needs of customers in a diversified manner. At the same time, the vertical upgrade of stacker products will continue to enhance the technical added value of the products, and the horizontal expansion will be carried out to develop more new products that can meet the needs of customers in different working conditions.

The persistent pursuit of technology has given ROBOTECHLOG a unique competitive advantage in the development process. At the 2021 Asia International Logistics Technology and Transportation System Exhibition (CeMAT ASIA 2021), ROBOTECHLOG launched a new stacker product represented by E-Smart, which integrates virtual commissioning, cloud platform, vision technology, Cutting-edge technologies such as 5G communication break through the traditional stacker system solution with new thinking and technology, enabling stacker products to enter the era of intelligence.

At present, the overall layout of 5G, digitization and intelligence has achieved initial results in the technical level of ROBOTECHLOG stacker cranes. In order to further improve the timeliness and success rate of project delivery, ROBOTECHLOG is carrying out a comprehensive reform of "speed-increasing and efficiency-enhancing", carrying out R&D and design on the modularization and standardization of stacker products, and reducing customer costs through lightweight equipment and high standardization. Manufacturing costs, improve the automated manufacturing level of stackers, improve quality and delivery speed, and greatly shorten the return on investment cycle.

In the future, ROBOTECHLOG will continue to develop the smart logistics track, and strive to maintain its own industry competitive advantage by continuously improving product technical competitiveness and delivery rate, and provide a lasting driving force for the global intelligent development.

ROBOTECHLOG is listed among the TOP-3 global stacker crane (SRM) manufacturers, leading smart logistics with strength

- Categories:News

- Author:

- Origin:

- Time of issue:2022-09-06 09:34

- Views:

(Summary description)

ROBOTECHLOG is listed among the TOP-3 global stacker crane (SRM) manufacturers, leading smart logistics with strength

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2022-09-06 09:34

- Views:

Recently, As an international authoritative logistics and supply chain research & consulting company, LogisticsIQ released the "Global Industrial SRM (Storage and Retrieval Machine) Ranking Analysis" list. With its outstanding innovation ability and technical strength, ROBOTECHLOG has won the global TOP20 stacker manufacturing enterprise. , in the Top 3.

"Global Industrial SRM (Storage and Retrieval Machine) Ranking Analysis" list from Revenue & Installation, Geographical Presence, Industry Coverage, Technological Advancement, Customer Satisfaction and other multi-dimensional evaluations to select the global TOP20. The list is recognized as the vane of the development of the global automated warehousing market. According to the Logistics IQ report, SRM (Storage and Retrieval Machine) has always been the core equipment of production logistics and manufacturing storage systems. As the need for automation increased, SRM created its own space in the multi-billion dollar market for material handling equipment.

ROBOTECHLOG brand was founded in Dornbirn, Austria in 1988. In 2014, it took root in China and realized the "localization" strategy of stacker equipment, realizing team localization and product localization. As the first equipment manufacturing provider to realize large-scale and mass production of stackers in China, it has global sales, operation and service capabilities in more than 20 countries and regions around the world, and has realized industrialization for more than 100 sub-sectors Empowerment, the global equipment sales have reached 4000+ sets/sets. Became the first core equipment supplier in the industry to realize "product development、personalized customization、mechanical manufacturing、electrical implementation、software integration" in China.

Facing the rapid development of the global intelligent logistics equipment market in recent years, ROBOTECHLOG has always focused on the R&D and manufacturing of stacker products, deeply cultivated the market, launched a variety of dedicated stacker models for multiple segments, and worked with industry partners to create a variety of scenarios. Smart logistics solutions, covering new energy, optical fiber, tobacco, aviation, food and beverage, automobile, medicine, cold chain, 3C, power and other industries.

ROBOTECHLOG always adheres to the innovation point of customer demand, and continuously develops and innovates to achieve full scene coverage with all categories of products. Through 7 series of products of PANTHER, ZEBRA, CHEETAH, BULL, GIRAFFE, LION and DORADO, we can meet the needs of customers in a diversified manner. At the same time, the vertical upgrade of stacker products will continue to enhance the technical added value of the products, and the horizontal expansion will be carried out to develop more new products that can meet the needs of customers in different working conditions.

The persistent pursuit of technology has given ROBOTECHLOG a unique competitive advantage in the development process. At the 2021 Asia International Logistics Technology and Transportation System Exhibition (CeMAT ASIA 2021), ROBOTECHLOG launched a new stacker product represented by E-Smart, which integrates virtual commissioning, cloud platform, vision technology, Cutting-edge technologies such as 5G communication break through the traditional stacker system solution with new thinking and technology, enabling stacker products to enter the era of intelligence.

At present, the overall layout of 5G, digitization and intelligence has achieved initial results in the technical level of ROBOTECHLOG stacker cranes. In order to further improve the timeliness and success rate of project delivery, ROBOTECHLOG is carrying out a comprehensive reform of "speed-increasing and efficiency-enhancing", carrying out R&D and design on the modularization and standardization of stacker products, and reducing customer costs through lightweight equipment and high standardization. Manufacturing costs, improve the automated manufacturing level of stackers, improve quality and delivery speed, and greatly shorten the return on investment cycle.

In the future, ROBOTECHLOG will continue to develop the smart logistics track, and strive to maintain its own industry competitive advantage by continuously improving product technical competitiveness and delivery rate, and provide a lasting driving force for the global intelligent development.